New Scale camera focus modules for mini OEM cameras

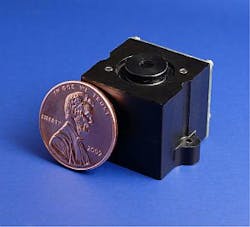

The M3-F focus module is designed for miniature OEM cameras used in portable biometric sensors, targeting, surveillance systems, and medical diagnostic and imaging devices. It measures 20 × 22 × 18.5 mm and improves image quality over a wide range of focus distances without adding volume or significantly increasing power use.

New Scale Technologies

Victor, NY

www.newscaletech.com

-----

PRESS RELEASE

Miniature M3-F focus modules provide precise lens motion in a fully integrated package for the smallest OEM cameras

Module assembles directly to board-mounted camera, accepts a standard threaded lens, operates on 3.3V and accepts high-level digital motion commands

Victor, NY – June 7, 2010 – New Scale Technologies, Inc. (www.newscaletech.com) today announced its M3-F focus module (www.newscaletech.com/M3-F.html) for miniature OEM cameras used in handheld products; portable biometric sensors; targeting, surveillance and security systems; and medical diagnostic and imaging devices. At only 20 x 22 x 18.5 mm – about the same dimensions as a fixed lens holder – the M3-F focus module improves image quality over a wide range of focus distances without adding volume or significantly increasing power usage.

All lens motion functions are fully integrated in the M3-F module including actuator, position sensor, guide mechanism, drive and control electronics and software. This extreme level of miniaturization and integration highlights New Scale’s micro-mechatronics capabilities.

With on-board closed-loop PID control, M3-F modules are designed for ease of integration. The microprocessor accepts PID closed-loop system tuning commands, as well as high-level input commands such as “move specified distance,” via standard serial interface (I2C, SPI or USART). No external controller is needed.

Modules provide millimeters of lens motion with 0.5 micrometer position resolution, better than 30 micrometer accuracy, and better than +/-0.5 degree angular alignment. Based on New Scale’s M3 micro-mechatronics module design platform (www.newscaletech.com/M3-micro-mechatronics.html), the M3-F modules are quickly customized to OEM specifications for lens (from M8 to M12 size, up to 5 grams mass), image sensor, focal length, board camera PCB mounting pattern, and other requirements.

M3-F modules accept 3.3V input voltage for battery-powered operation. They draw approximately 470 mW of power while moving and 130 mW quiescent. Weight is approximately 6 grams without lens.

“The M3-F incorporates New Scale’s state-of-the-art precision miniature mechatronics into a focus module for the precise positioning required by today’s high-resolution camera systems,” said Ralph Weber, product manager at New Scale. “Integrating the motor driver, position sensor and microprocessor right into the module dramatically simplifies system integration for our customers, and our flexible M3 design platform enables us to create customized modules very quickly for each OEM.”

M3 Platform advances New Scale’s focus technology

The M3-F modules advance New Scale’s custom focus module technology by:

- Integrating the drive electronics in the module, reducing system size and weight.

- Adding a microprocessor in the module for closed-loop PID control, simplifying system integration for OEM users.

- Building on New Scale’s new M3 Micro-Mechatronic Module Design Platform, facilitating rapid customization.

Each M3 Micro-Mechatronics Module incorporates a patented piezoelectric SQUIGGLE micro motor, a motor drive ASIC, a TRACKER magnetic position sensor, a microprocessor and a motion mechanism in a compact housing. M3 modules are smaller, more powerful, more precise and even easier to integrate than traditional electromagnetic motor systems.

-----

Posted by Lee Mather

Subscribe now to Laser Focus World magazine; it's free!