Laser-plasma accelerator: A new tool to quantitatively image atomizing sprays

DIEGO GUÉNOT, OLLE LUNDH, and EDOUARD BERROCAL

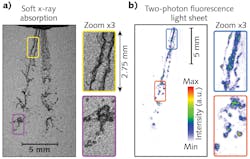

Atomizing sprays are widely used toinject liquid fuel into combustion enginesin vehicles, ships, and aircraft. Understanding the physics of the liquid/gas phase transition is very important for designing more efficient and environmentally friendly vehicles with significantly reduced pollutant emissions. Tostudy atomizing sprays, a proof-of-concept laser-plasma accelerator is a new way of visualizing challenging transient scattering media using simultaneous soft x-ray absorption and two-photon laser-induced fluorescence (2p-LIF).1Fusing the simultaneous images from soft x-ray absorption and 2p-LIF has two advantages. First, it minimizes blurring effects due to multiple light scattering, and second, it provides highly complementary spray information. While x-ray absorption allows the quantification of liquid mass distribution, the 2p-LIF images yield high-contrast images of the droplets, ligaments, and other irregular liquid structures (see Fig. 1). These laser-plasma accelerator snapshot images of relatively large viewed areas (2 × 2 cm) will expand scientific understanding of the physics of liquid atomization.

Applications of spray systems

Spray systems are used for dispersion of medicines into human airways, painting and coating of surfaces, producing powders via spray-drying in the food and pharmaceutical industries, dispersion of agricultural chemicals on crops, cutting of metals using waterjet cutters, extinguishing fires, cooling hot environments, injecting ink in printers, delivering cell suspensions to treat burn injuries, and so forth. Nevertheless, the most important application is the injection of liquid fuel into piston and gas-turbine combustion engines to generate the necessary mechanical power in combustion-based vehicles and devices used for transportation.

Liquid fuels contain much more energy per unit volume than gas-phase fuels and they are easy to store and transport. However, liquid fuel combustion is a major source for emission of pollutants such as nitrous oxide, hydrocarbons, carbon-monoxide and dioxide, and soot. The reduction of atmospheric pollution emissions implies the development of more efficient/clean liquid-fuel-driven combustion devices.

One direct way to achieve these goals is to use—for each combustion device—the appropriate spray system where the desired size, velocity, concentration, trajectory, and evaporation of droplets are produced. This approach also holds for the injection of future alternative fuels, including ethanol blends or biodiesel. This necessitates the need to better understand the process of liquid atomization to improve and control liquid fuel combustion.

Direct observations of sprays are largely limited by the multiple light scattering caused by the droplets and the refraction/reflections from large liquid bodies that limits the amount of quantitative information currently accessible for atomizing sprays. In other words, the scattering nature of atomizing sprays is responsible for blurring and hiding any complex fluid mechanical processes responsible for liquid breakups.

Additional issues include the need to capture images of very fast events and manage the multiscale nature of spray systems (from micrometer to centimeter scales). As a result, quantitative information and detailed visualization of the atomization process is still missing and limiting progress in the development of analytical and numerical models that could make reliable predictions of spray formation.

Fusing x-ray and fluorescence images

To overcome problems related to multiple light scattering and image blurs, the experimental development of advanced imaging techniques has increased over the past two decades. Several optical methods that reduce the contribution from multiple light scattering use different filtering approaches, including the use of time-gating,2 structured illumination,3 and more recently, 2p-LIF light-sheet imaging.4

The advantage of 2p-LIF detection in optically dense sprays is its ability to provide much-higher image contrast than one-photon liquid LIF or elastic scattering. The main reason for this is that multiple scattered photons spread in space and time, greatly reducing the probability of having two photons simultaneously absorbed by a fluorescence tracer.

On the contrary, at the location where the illuminating light sheet is focused, the probability for the 2p-LIF process to occur is at its highest, providing a signal that is generated only at the object plane of the camera objective. Consequently, light-sheet 2p-LIF provides images with high fidelity of the liquid bodies and reveals void structures. Thus, 2p-LIF light-sheet imaging can provide details of small droplets and small liquid elements that are not visible with conventional imaging approaches.

Another solution to suppress the occurrence of multiple light scattering is to use x-rays. Unlike visible light, the refractive index of the injected liquid, such as water, becomes close to unity for photons in the kiloelectronvolt (keV) range, while absorption is greatly increased. Thus, for x-ray radiography, the signal is primarily due to absorption and not scattering, making this approach the most reliable for measuring liquid mass distribution in the near-nozzle region, where large and irregular liquid structures are still present and where the liquid density is the highest.

As the liquid mass distribution is related to the rate of liquid breakup and to gas entrainment, this quantity is critical for understanding how sprays are formed. Due to the short time scale (usually inferior than a microsecond) of the breakup processes and the high x-ray flux required to reach such time resolution, most research efforts related to radiography of transient sprays have been accomplished at synchrotron facilities such as the Advanced Photon Source at Argonne National Laboratory (Lemont, IL).5

A novel solution for generating high-flux soft-x-ray pulses for spray imaging is using a compact laser-plasma accelerator. As x-rays are generated from high-energy femtosecond laser pulses, a fraction of the incident pulse is also used to generate a 2p-LIF signal. Using this unique configuration, advanced optical and x-ray imaging can be used simultaneously, providing complementary information about the spray interior.

Femtosecond x-rays from a laser-plasma accelerator

At the Lund Laser Centre, a method for particle acceleration is being studied that allows electrons to ‘surf’ on waves of plasma—a hot gas of charged particles—and gain high energies (hundreds of mega electron volts) in short distances (millimeters).

In the laser wakefield accelerator, the intense laser pulse (1 J, 30 fs) is focused in a helium gas that is immediately ionized, producing a plasma (see Fig. 2). The laser pulse pushes electrons away while leaving the heavier ions almost stationary on the laser timescale. The resulting charge separation drives a longitudinal plasma wave that follows in the wake of the driving laser pulse (hence the term wakefield).This wave can support extreme electric fields—more than 100 gigavolts per meter and orders of magnitude higher than in traditional accelerators. If a bunch of ‘witness’ electrons are injected in the right location and with the right energy, they will catch and surf the plasma wave, quickly gaining relativistic velocities close to the speed of light as they accelerate. Experimentally, this can be achieved by simply mixing a small amount of nitrogen with the helium gas.6

The plasma accelerator itself can produce a beam of x-rays. In addition to strong forward acceleration by the wakefield, a radially focusing force causes accelerated electrons to oscillate in the transverse direction (so-called betatron oscillations) and therefore emit kiloelectronvolt x-rays in the forward direction—much in the same way as when relativistic electrons pass through the periodic magnetic field in an undulator. The ultrashort x-ray pulse is intrinsically synchronized to the laser, which provides a unique platform to study fast and ultrafast phenomena with high spatiotemporal resolution.7, 8

For example, for spray imaging, one portion of the laser pulse can be used for x-ray radiography, while another portion can simultaneously image the spray using advanced optical techniques such as 2p-LIF. The soft x-rays produced by the laser-plasma accelerator are ideal for measuring liquid absorption over a fraction of a millimeter, integrated along the spray path. In addition, the diverging x-ray beam allows imaging of relatively large spray sections (centimeters) after a short propagation distance (meters).

Quantitative measurements of liquid mass

The role of the calibration is to convert x-ray intensity into equivalent path length (EPL). The EPL sensibility of the x-ray measurement is determined by calculating the amount of water needed to cause absorption larger than the noise of a single-shot image. The noise is defined as the root-mean-squared (rms) fluctuation. Using a calibration absorption curve, the amount of water needed to generate a signal loss higher than the noise can be deduced (see Fig. 3).Note that when crossing the liquid jet, the spectrum changes—an effect known as “beam hardening” that changes the absorption properties. Therefore, the amount of water detectable is reduced with distance. This drop in the liquid mass sensibility can be mitigated by using higher-energy photons.

For sprays having a liquid path length around 100 µm, the optimal energy is 4 keV for pure water; for a 500 µm liquid path length, the best energy is around 7 keV. Another option is to change the concentration of potassium iodide (KI) in the mixture to match the energy—but this comes at the cost of a change in liquid properties (surface tension and viscosity).

Finally, by averaging more than 50 calibrated radiography images, the statistical time evolution of the liquid mass distribution is obtained (see Fig. 4).Lund University has demonstrated the ability to use intense femtosecond laser pulses for simultaneous x-ray and optical imaging (by laser-plasma acceleration and two-photon fluorescence, respectively) of the dynamic evolution of a spray system typically used in internal combustion engines. The results show that the sensibility to liquid mass is comparable (if not better) to what has been achieved so far with synchrotrons. In addition, the quantitative x-ray images may make it possible to achieve tomographic 3D reconstruction.

Further studies of sprays, or other transient scattering media, will be completed in the future using laser-plasma accelerator facilities. In the long term, this will boost the development of cleaner and more-efficient combustion engines.

REFERENCES

1. D. Guénot et al., Optica, 7, 2, 131–134 (2020).

2. M. A. Linne et al., Proc. Combust. Inst., 32, 2, 2147–2161 (2009).

3. E. Berrocal et al., Opt. Express, 16, 22, 17870–17881 (2008).

4. E. Berrocal et al., OSA Continuum, 2, 3, 983–993 (2019).

5. A. G. MacPhee et al., Science, 295, 1261 (2002).

6. I. Gallardo Gonzalez et al., New J. Phys., 20, 053011 (2018).

7. K. Svendsen et al., Opt. Express, 26, 26, 33930–33941 (2018).

8. B. Kettle et al., Phys. Rev. Lett., 123, 254801 (2019).

Diego Guénot is postdoctoral fellow in atomic physics, Olle Lundh is university lecturer in atomic physics, and Edouard Berrocal is senior lecturer and researcher in combustion physics, all at Lund University, Lund, Sweden; e-mail: [email protected]; www.forbrf.lth.se/english and https://spray-imaging.com.