Biomedical Optics Design: Software speeds development of biomedical optics

Making an optical device work as planned depends on a wide range of features. In the past, engineers often developed new elements from back-of-the-envelope calculations followed by prototyping and testing. That process takes lots of time and resources, plus it depends on uncertainties that often produce a product that fails to meet the desired performance characteristics. Today's way—using optics design software—delivers faster and more accurate calculations and devices that can be simulated in silicon. Today's designers of biomedical optics systems are blessed with an abundance of software options, including offerings from Breault Research Organization (Tucson, AZ) and Synopsys (Mountain View, CA). To learn more about optical design software and the capabilities it offers for life scientists, BioOptics World talked with a professor who teaches tomorrow's optical engineers to use these tools, a programmer who developed a widely used open-source platform, and makers of three commercial packages: Lambda Research's (Littleton, MA) TracePro, Photon Engineering's (Tucson, AZ) FRED Optical Engineering Software, and Zemax's (Redmond, WA) OpticStudio.

Software skills: indispensable

To work in optics, especially in the future, software skills will be indispensable. As José Sasián, professor of optical sciences at the University of Arizona at Tucson, says, "What I tell my students is: When they graduate, you'll be in a meeting room with engineers, and everyone will have a laptop running programs like optics design and MATLAB."

While Sasián points out that "all of the leading programs produce nice graphics," really getting the most from the software "comes from making the time to learn about it." He adds, "Getting the most from a program also requires an understanding of optics and lens design."

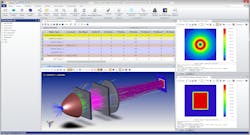

Rich Pfisterer of Photon Engineering advises thinking of FRED as a virtual prototyping tool for the development and analysis of hardware systems. "Building hardware takes time and money and can be risky-the system may not work!" he says. "FRED makes it possible to simulate the hardware in software rapidly and accurately, and so it is a cost-effective tool for many biomedical applications developers."

Many optics engineers can benefit from such software because it can be used to design many devices-from endoscopes, microscopes and telescopes to cameras and zoom lenses. "It is essentially solids modeling (that is, computer-aided design) software that can propagate light through an arbitrary 3D physical geometry," says Pfisterer.

As Akash Arora, product manager at Zemax, says, "Our software can be used for almost anything with optics in it." He adds, "We have a customer in almost any industry you can imagine." To add to the list, he mentions contact lenses, retinal research, and laser systems.

Pfisterer notes that users can construct complex optomechanical models using primitive structures (spheres, blocks, pipes, etc.) or imported CAD files developed elsewhere. And light sources of any complexity can be created within the program or imported from manufacturers. Optical properties such as coatings, polarization/birefringence, and scatter can be assigned to structures to simulate such phenomena as the scatter from skin under illumination, fluorescence (including wavelength shift) of biological sample, or thermal emission (e.g., of tissue that has been cooled for surgery). Since the software can model coherent and incoherent light propagation, users can construct accurate models of optical coherence tomography (OCT) systems and perform virtual experiments; combine a laser model with a volume scatter model to simulate a flow cytometry system; or simultaneously model the illumination of a biological sample and the imaging performance of an endoscope.

Analyzing the output

Arora says, "The primary job of the software is to simulate an optical system, so that you don't waste resources prototyping or building it to see how it works." To achieve that, the software must create a system that meets the desired specifications and is insensitive to errors in fabrication.

Once an optics engineer creates the desired system with Zemax's OpticStudio, the software produces a set of descriptions and drawings of the lenses or mirrors, which can be sent to a manufacturer (see Fig. 1). "It looks like a schematic or any mechanical drawings," says Arora. "It calls out the key dimensions and tolerances for the fabrication to work properly."

This program can also turn the information into a common computer-aided design (CAD) format that goes directly to a computer numerical control (CNC) machine that makes the optical part. As Arora says, however, "You come up with a system that will meet your goals before you grind a single piece of glass."

To get the most from this software, though, a user with experience in optics gets a huge head start. As Arora says, "Our interface is easy to use, but this software models complex phenomena and having an understanding of light, geometrical ray tracing, and so forth helps out tremendously."

Getting up to speed with this software also depends on the hardware. Most any computer can run OpticStudio. For example, Arora runs it on his Microsoft Surface Pro 3. Still, a machine with more cores runs the program faster. In fact, it's a linear relationship—doubling the cores, for example, doubles the speed. In addition, OpticStudio can take advantage of relatively large computers. The current version can make use of as many as 64 cores. The company did, however, make a special version of the software for a customer who wanted to use 128 cores, and the hardware still provided a linear improvement in speed.

Tech training

For want-to-be experts on Lambda's TracePro, the company will train you. Mike Gauvin, the company's vice president of sales and marketing, talked to BioOptics World about the software and the classes.

According to Gauvin, TracePro excels in its visual approach and ease of use. He says, "You can quickly sketch optics as surface profiles and interactively ray trace through the sketched optical component to see how light interacts in 2D or 3D." This program will also analyze an optical system for various criteria, such as flux, uniformity, or color. He says, "We've seen designs where a very small change in an optical component doubled the power out of a lens using our optimizers."

To really use the full capabilities of this program, users can take a five-day training course but many users learn the program on their own using Lambda Research's website videos, webinars and online tutorials. The five-day course starts by teaching a user how to get the desired geometry into the program and then add optical properties. As the course goes on, participants learn to optimize elements and systems. In the advanced portions, the course even teaches people to write their own code into the software and shows them how to remove stray light.

When asked who takes these classes, Gauvin says, "Everyone from CAD designers through Ph.D. optical engineers." Of course, the other software developers offer training, too.

Solving your own problems

Paul Lutus started solving his own problems years ago. He designed components for NASA's space shuttle and developed a mathematical model of the solar system that was used in the Viking Mars mission. Then, he switched to computer science, and 11 years ago he wrote OpticalRayTracer.

He says, "I originally wrote it to meet my own needs, but it's now producing substantial academic interest as an educational tool." Better still, it's free (see Fig. 2).Lutus first wrote OpticalRayTracer in C++, and it started with a single optical axis. He says, "User-defined lenses had to align with a single light pathway, and only refractive optical elements were allowed—convex and concave." He kept adding features. He also rewrote OpticalRayTracer in Java.

Today, says Lutus, "OpticalRayTracer supports three kinds of optical elements—refractors, reflectors, and absorbers." He adds, "For each surface of these elements, the user can define a numerical curvature, positive or negative, derived from one of four mathematical classes: spherical, parabolic, hyperbolic, and planar." Also, this program now handles complex optical axes. Lutus says, "Both the light paths and the optical elements can be freely positioned and rotated." Moreover, anyone can use this program to learn about optics (see Fig. 3). "The user moves lenses around by dragging with the mouse cursor, and as the lens moves, the traced light rays update interactively," says Lutus.It's a new world when it comes to designing optics. No one needs to do back-of-the-envelope calculations today. The tools available let you play with all kinds of designs and watch the results unfold in front of you. The options are endless.

Mike May | Contributing Editor, BioOptics World

Mike May writes about instrumentation design and application for BioOptics World. He earned his Ph.D. in neurobiology and behavior from Cornell University and is a member of Sigma Xi: The Scientific Research Society. He has written two books and scores of articles in the field of biomedicine.