Simulation and Modeling: Simulation provides intelligent laser choice for two-photon microscopy

KARL BEESON, MARY POTASEK, and EVGUENI PARILOV

Two-photon scanning microscopy, which is based on natural or artificial fluorescent probes, is now one of the primary means for monitoring and quantifying biomedical processes in living or preserved tissue.1-5 Finding the right combination of probe and laser for a desired class of biological samples is the defining step in two-photon microscopy.

Because laser prices vary significantly, it is particularly important to choose the best laser for the money without suffering a substantial loss in laser efficacy. Using simulation software, it is now possible to make an intelligent choice for a laser without having to obtain any lasers for on-site measurements.

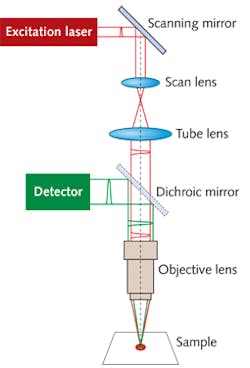

To increase light penetration depth in biological tissue, two-photon scanning microscopy typically uses high-intensity infrared lasers rather than the visible light sources that are normally used for one-photon microscopy. Following two-photon absorption, the probe molecules can emit visible-wavelength fluorescence and phosphorescence that can be easily detected. A schematic diagram of a two-photon scanning microscope is shown in Fig. 1.

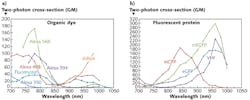

Two-photon cross-sections (in units of GM, named after Maria Göppert Mayer) are shown in Figure 2 for some organic dyes (Fig. 2a) and fluorescent proteins (Fig. 2b) in the wavelength range from 700 to 1050 nm.6 Many common fluorescing dyes and proteins can be excited by a wide range of infrared wavelengths, allowing the use of fixed-wavelength excitation lasers such as femtosecond fiber lasers.Types of lasers for two-photon scanning microscopy

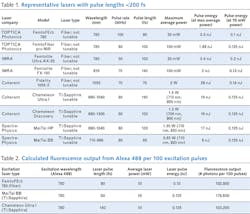

Two-photon microscopy requires high laser pulse intensity. The highest-intensity pulses are generated by lasers with pulse widths of about 200 fs or less. For example, the variable-wavelength titanium:sapphire (Ti:sapphire) lasers and some types of fixed-wavelength fiber laser generate pulses in the 80–140 fs time range.

Although Ti:sapphire lasers are widely used due to their high output power (greater than 1W in some cases), high intensity, and wide tunability (on the order of 680 nm to 1040 nm), they are very expensive (about $150,000 or more) and take up considerable space in a characterization laboratory. In addition, the high output power of these lasers can generally not be fully used due to potential tissue damage.

The maximum useful average power for scanning biological samples is approximately 10 mW or less. For the calculations described below, we will therefore assume that the example lasers all have 10 mW of average power at the light-incident surface of the samples.

A few representative examples of variable- and fixed-wavelength lasers with pulse widths of 200 fs or less are listed in Table 1 along with the operating wavelength, pulse rate, pulse length, maximum average power, pulse energy at maximum average power, and pulse energy at 10 mW average power. Four models of Ti:sapphire lasers are in Table 1.New types of fixed-wavelength fiber lasers are now available that can replace Ti:sapphire lasers in many routine two-photon microscopy applications. Two examples are fiber lasers that operate at 780 nm or at about 1055 nm. Light at 780 nm is generated by frequency-doubled erbium (Er)-doped fiber lasers and is suitable for many fluorescent organic dyes and fluorescent proteins, as shown by the example spectra in Figure 2. Light of about 1055 nm can be generated by, for example, ytterbium (Yb)-doped fiber lasers. Some fluorescent proteins including dsRed can probably be excited by 1055 nm lasers even though the excitation spectrum shown in Figure 2 does not extend to that range. Femtosecond lasers operate at pulse-repetition rates of 50 to 100 MHz.

Simulations of light emission from single and multiple laser pulses

When looking for an alternative to a usually expensive Ti:sapphire laser, we can pre-test lasers by performing numerical calculations using the SimphoSOFT simulation platform. This software can numerically solve the rate equations, which describe the dynamics of the probe molecule energy levels, and simultaneously solve the propagation equations for light traversing the sample filled with probe molecules.

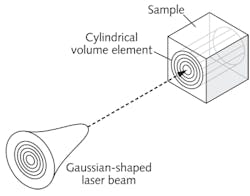

Its mathematical model can accurately predict the fluorescence and phosphorescence emission spectra at any position in a sample, starting at the light-incidence surface. The user provides the beam radius at the input surface, which in these examples is 0.5 μm, as well as the emission spectrum. The beam radius is determined by the numerical aperture (NA) of the microscope objective lens. The spectrum is provided by either a table of values or a Gaussian-shaped (or Lorentzian-shaped) function. We used a published source7 to get the table of values for Alexa 488. A schematic diagram of a laser beam directed at a cylindrical volume element of the sample that we specify for calculating the number of emitted photons is shown in Figure 3.The rate of photon emission is related to the population of the singlet excited state divided by the fluorescence lifetime τ (for Alexa 488, τ = 4.1 ns). In general, probe molecules can also be excited to higher excited states (or even triplet states); emission from these states can also be calculated by the software. To get the total emitted fluorescent photons, the software integrates the photon emission rate over the volume element width and radius and over the specific time range (10 ns in this case).

A 100 MHz laser emits a pulse every 10 ns, or 100 pulses every 1 μs. If the 100 MHz laser is scanned across the sample at a rate corresponding to 1 μs per image pixel (that is, 100 pulses per pixel), a 1000 × 1000 pixel image can be acquired in the relatively short time of 1 s. For scanning two-photon microscopy, it is quite reasonable to use 100 or more laser pulses per image pixel; for example, 1028 photons emitted in one pulse become ~102,800 photons for 100 pulses, which is more than sufficient for high-quality imaging (see Table 2).

We calculated the number of fluorescent photons generated from the dye Alexa 488 by 100 pulses from two well known models of Ti:sapphire laser and one fiber laser (the TOPTICA Photonics FemtoFErb 780) to compare their performance for two-photon microscopy. The results in Table 2 indicate that one can use a cheaper fiber laser to reach approximately the same image quality as is achieved via a typical expensive Ti:sapphire laser. The last column of Table 2 shows a quantitative comparison of the fluorescence signals from the Alexa 488 probe predicted by SimphoSOFT for different excitation lasers.

Simulation software makes it possible to predict the efficiency of two-photon microscopy devices without doing lengthy on-site experiments. Software can save tremendous amounts of time choosing the laser(s) to purchase for two-photon microscopy in order to get high performance at reasonable cost.

Acknowledgment

We thank Dr. Igor Pastirk, Toptica Photonics USA, for many helpful suggestions.

References

1. P. T. C. So, et al., Annu. Rev. Biomed. Eng. 02, 399–429 (2000).

2. L. Sacconi, et al., Biomed. Opt. Let. 12(5), 050502-1–050502-3 (2007).

3. W. Denk, et al., Science 248, 73–76 (1990).

4. M. Jain, et al., Arch. Pathol. Lab. Med. 136, 517–526 (2012).

5. C. Xu and F.W. Wise, Nat. Photon. 7, 875–882, (2013).

6. "Two-photon action cross sections," www.drbio.cornell.edu/cross_sections.html.

7. Fluorescence SpectraViewer, http://www.lifetechnologies.com/us/en/home/life-science/cell-analysis/labeling-chemistry/fluorescence-spectraviewer.html.

Karl Beeson is executive VP, engineering; Mary Potasek is president; and Evgueni Parilov is executive VP of R&D at Simphotek Inc., 211 Warren St., Newark, NJ 07103; email: [email protected]; www.simphotek.com.