"Please step into this booth for your body scan."

Such a phrase, with its medical connotations, may someday become a familiar request—and one heard at your local clothing store rather than your doctor's office. In the apparel industry, a body scan is a key element in the so-called mass-customization of clothing. In such a scheme, the customer undergoes a body scan that captures body shape; the information is then sent to a computer, which calculates the specifications for various items of clothing. Based on the computer's output, a so-called agile manufacturing plant then cuts and sews fabric into the finished attire.

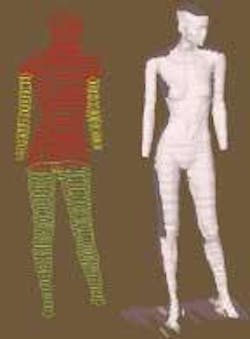

But today's commercially available body scanners are too expensive for most stores. In addition, the computer software visualizes only a two-dimensional fabric pattern, requiring that the garment actually be made before design effects can be seen. Researchers in the Department of Human Ecology at the University of Texas at Austin have developed a potentially inexpensive body scanner combined with computer software that produces a three-dimensional (3-D) digital model of the body and its clothing.1 The software allows the designer to alter garment characteristics such as looseness while the customer looks on, before the garment is manufactured.

The scanner, which is housed in a 5 × 8 × 8-ft booth, is based on laser triangulation. The booth contains two vertical linear stages that each carry an eye-safe multiple-laser line projector and a CCD camera. A computer directs the stages to perform measurements; the stages stop half a dozen times in their travel to capture data. Individual laser scans are filled in to create a 3-D image (see figure). Areas of complex shape such as knees receive overlapping scans. Image-processing techniques such as adaptive thresholding and curve fitting unite scan lines that are broken and of varying brightness. An interpolation computation then produces a smooth body surface.

In addition to affordability, the goal has been to develop a scanner that is more portable, compact, and fast, says Bugao Xu, one of the researchers. "The whole body scan takes about five seconds and the scanned images can be viewed in a few seconds," he says.

Virtual clothing

The researchers also developed software that dresses the depicted 3-D figure in a "virtual garment." The program allows seams and other structural details to be added to the item of clothing. Vertical and horizontal sections can be taken through the body image and virtual cloth to check looseness of the garment at any location. The clothing designer can then alter the virtual garment's shape and looseness.

REFERENCE

- Bugao Xu et al., Optical Eng. (July 2002).