How to keep track of the optical design process

How to keep track of the optical design process

Scott W. Weller

Customized lens documents and a database-management approach make optical design information

easily accessible to designers.

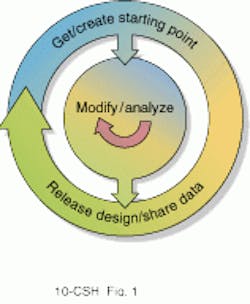

Optical design is a complex process involving a diversity of tasks, from the mundane to the artistic. The routine, clerical tasks in optical design represent an inherent productivity limit that must be addressed if modern designers hope to remain competitive. If we view optical design as a process, it is clear that the core modify/analyze function is well served by a plethora of commercial design tools (see Fig. 1).

The peripheral functions, including finding design starting points, tracking the design process, producing a final design release, and sharing design data with other members of an engineering team remain human-intensive and without software support. While other design domains such as software development have adopted sophisticated configuration-management tools, optical designers have been left to their own devices to develop informal procedures to address these peripheral tasks.

The problem

From a business standpoint, designers should spend the bulk of their time designing. Once a design is complete, however, it is essential that the data be shared with metrology and manufacturing engineers in a way in which it can be used. In addition, any company hoping to achieve ISO 9000 certification must establish and adhere to certain procedural standards, which only adds to the peripheral tasks performed by the optical designer.

When beginning a new design, the optical designer`s first question is, "Where are the data I need?" The answer typically involves visual searches over directory and/or lens data-file listings. This approach relies on clever file naming or lens titles to encode a variety of context-specific information and, by definition, involves individualized artifacts rich in content and low in information. For example, the file names `anascook,` `anashek,` and `anastsr` may identify a Cooke triplet, Hektor anastigmat, and a split-rear crown triplet, but only the originator is likely to know that. Moreover, to actually view the system and performance parameters, the follow-up designer must go into each file and run analysis modules, a time-consuming task.

Modern optics software allows the proficient designer to develop many parallel design paths and can even produce generations of designs automatically, all of which must be evaluated and then pursued or discarded based on their individual merits. Copious notes, usually in the designer`s own hand, document the design genealogy. This common practice offers little support for the modern designer, who must retrace his or her steps, and certainly provides little documentation for engineering team posterity. An unfortunate consequence is that senior designers continue to act as resource personnel for designs crafted early in their career.

Finally, the output of the optical design process is based on a lens data file, which is of little use to metrologists or fabrication teams. Here again the designer acts as analytical support staff, generating data reductions that are meaningful to these other engineers. More-effective mechanisms for dispersing optical design data in usable forms is clearly necessary.

A software solution

After considering these issues for some time, it occurred to me that instead of working with raw optical-system data, we should be working with what I call lens documents. Rather than relying on simple artifacts such as file names and written logs, we should view both ends of the design process as a database problem.

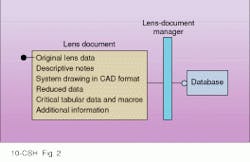

A lens document is more than optical system data and thereby lends itself to content-based searches and archiving mechanisms that can hide the details of storage while facilitating data sharing (see Fig. 2). A lens document nominally includes the original optical system data in its commercial format; a detailed system description and drawing; design notes; a variety of precalculated data items such as f/number, focal length, measure of manufacturability, and number of elements; designer-specified descriptors such as system type, application, and so on; critical tabular data such as through-focus modulation-transfer-function data, with the commands or macros that were used to generate them; and design release procedures. All of this is packaged so that it can be manipulated as a unit.

Optical designers need to be able to search design files based on content, not just file name or title. At Optikwerk, we use a database-management system (DBMS) to archive lens documents, and we can retrieve the optical system data as a file when necessary. The DBMS used to archive the lens document allows complex searches over the items it contains. Once a document is found, we can browse through previously computed data, read design notes, and look at a system drawing, all without recomputation.

This approach allows a designer to pursue many branches when working on a design project. Lens documents can be archived at various stages of the design process, which simplifies returning to a previous design point. The designer`s attention is on the family tree of the design, not on the details of how the design points are stored.

With the DBMS, optical system data can easily be made available to other designers, engineers, and project managers. The lens document offers the optical system data in context, making data-sharing with peers more effective. This approach can also relieve the design originator of the need to support the on-going use of design data. In the case of sensitive data, the DBMS provides overwrite protection and secured access.

Implementation

To create a lens document, we obviously need the original optical system data and an optical design program to generate the various outputs. Once a lens document is created, a database manager is necessary to archive and manipulate it. We are currently developing a lens-document-management system for a large Rochester-based optics concern. Its needs include attaining ready access to a large library of proprietary designs, facilitating data-sharing between various engineering teams, and automating design release procedures as established in its ISO 9000 commitment.

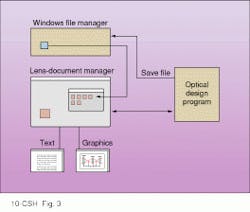

The lens-document concept is applicable to any commercial optical design program. As a proof of concept, we have developed a prototype lens-document manager that we attached to a widely used optical design program (CODE V; Optical Research Associates, Pasadena, CA). When a designer wishes to create a lens document, the lens-document manager loads the optical system data from the disk, and these data along with various user-supplied commands are sent through CODE V. The output from this run is displayed in text and graphics windows and is stored in the DBMS along with the original design data. Once stored, the lens document is displayed as a small icon, a long description, and various reduced parameters in project subwindows on the lens-document-manager main screen.

To browse through existing lens documents, the designer can perform a complex search or simply double click on a lens-document icon. When a lens document is selected, its optical system data are reloaded into CODE V for editing, and previously generated data are displayed in text and graphics windows without recomputation.

We are also completing work on a lens-document manager that will be available with the release of Optikwerks Pro 2.0, our commercial optics and laser CAD software. Optikwerks LensDocMan includes all of the facilities described above, including the creation, manipulation, and archiving of lens documents.

Optical design is not getting easier, and technology advances have not relieved us of the routine tasks peripheral to the actual work of designing lenses. Any mechanisms that facilitate the design and manufacturing process while hiding tiresome details simply makes good business sense. n

FIGURE 2. Lens-document approach to tracking design iterations provides summary information on an optical system without requiring the user to review the lens data from within the generating software.

FIGURE 3. Lens-document manager allows optical design files originating in a typical commercial design program to be easily assessed without recomputation.

SCOTT W. WELLER is president and CEO of Optikwerk Inc., 2604 Elmwood Avenue #330, Rochester, NY 14618.