Process Control: CLAMIR precisely controls advanced laser manufacturing processes

ARTURO BALDASANO RAMÍREZ

Industry 4.0 is pushing the industrial world to adopt new technology for introducing automation, along with specialized and sophisticated tools, in production lines. At the same time, other concepts such as “factories of the future” and “zero defects” force the implementation of new methods of fabrication, including faster, cleaner, more efficient, and reliable processes fully monitored and, when possible, controlled in real time. As an example of this industrial transformation and the implementation of these concepts, laser technology is being adopted as a replacement for traditional tools, with manufacturing processes being converted in this way for a wide range of industrial applications.

One of these laser techniques is direct energy deposition (DED). Among the different applications of DED, two are becoming widespread in the industry: laser metal deposition (LMD) and laser cladding, both of which are mainly used for additive manufacturing, coating, and repairing. Frequently, these processes require very long manufacturing times during which the initial conditions change dynamically while the process is running. This increases the need to integrate sensors and actuators into the production equipment that are capable of monitoring and controlling the key parameters of the process and adapting them dynamically to variations occurring during the manufacturing time.

Monitoring the melt pool

One of the process features that is most subject to change is the melt pool, or the area in which the light power is suddenly transformed into heat via an interaction between incident photons and matter. As a result, it makes sense to monitor and control the parameters affecting the melt pool: geometry, heat distribution, dynamics, temperature, and so on.

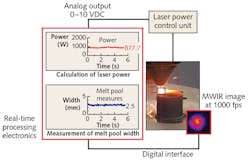

Control for Laser Additive Manufacturing with Infrared (CLAMIR) is a solution developed and commercialized by New Infrared Technologies that continuously monitors the melt pool and performs closed-loop feedback control of the laser power to maintain its properties at a constant throughout the process. CLAMIR uses a high-speed uncooled infrared (IR) camera as a main sensor, which is coupled coaxially into the laser optics, allowing the camera to obtain IR images of the melt pool at a 1 kHz frame rate. Based on real-time processing of the images performed internally by the camera, the system continuously extracts key parameters of the melt pool such as temperature gradients, geometry, area, and width. Using advanced algorithms for analysis and control, CLAMIR controls, in real time, the power of the incident laser with the objective of keeping the deposition process within the range of tolerances defined by the user (see Fig. 1). The capability of installing CLAMIR in an existing optical port makes it possible to be retrofitted into existing machines.

CLAMIR is a compact and rugged device that is compliant with robustness requirements demanded by the industry. The embedded system consists of three main subsystems: 1) the sensor, a high-speed IR camera sensitive in the 1–5 µm range and uncooled operation at room temperature (very important as regular maintenance of the camera is not necessary); 2) electronics for real-time image processing; and 3) electronics for process control.

MWIR has advantages

The use of a midwave-infrared (MWIR) camera results in exceptional performance compared with other vision technologies at other wavelengths such as traditional high-speed visible (VIS)-range cameras. A study carried out by the Spanish Center of Excellence (AIMEN; Galicia, Spain) and the research center Fraunhofer ILT (Aachen, Germany) concludes that high-speed MWIR imagers provide more valuable information than traditional high-speed VIS-CMOS cameras for monitoring laser welding and LMD processes. The advantage comes from the ability of MWIR cameras to observe wider temperature gradients with much more contrast before reaching saturation.1 The benchmarking analysis presented in this work showed that the most important features were extracted from MWIR imagers. In a list of the top-performing features, the first representative VIS feature was in the 34th position, giving an idea of the advantages of using the MWIR spectral band for monitoring and controlling laser welding processes.

CLAMIR includes a software tool that configures the system for a chosen production machine and process, logging of the process data (including the IR images), and visualization of the logged data.

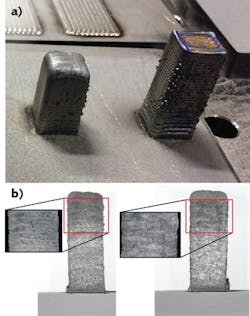

CLAMIR has been designed for real-time control of LMD and cladding processes using multiple process speeds and materials, and can be used with most of the existing laser optics in the market. The mechanical integration of CLAMIR in the laser optics is done by coupling the camera (via a C-mount) into an existing optical port, which needs to be capable of transmitting the process’ reflected light at wavelengths above 1.1 µm, as this is the wavelength range used by the IR camera to monitor the melt pool. Most current laser optics already have dichroic mirrors to bring this radiation into the optical port for observation purposes, making this integration quite straightforward.CLAMIR is currently a versatile tool for real-time control and monitoring of most existing LMD and cladding processes used in the industry (see Fig. 3). However, new applications are regularly arising that require the use of new materials, and more-complex and sophisticated new deposition processes are emerging. Different materials and structures will require modified process conditions. The CLAMIR concept was envisioned as an adaptable system able to suit new manufacturing methods, adding new control functionalities in a feasible way.

REFERENCE

1. J. Rodríguez-Araújo, A. Garcia-Diaz, V. Panadeiro, and C. Knaak, Imaging and Applied Optics 2017, ATh2A.2; https://doi.org/10.1364/aio.2017.ath2a.2.

Arturo Baldasano Ramírez is CEO of New Infrared Technologies (NIT), Madrid, Spain; e-mail: [email protected]; www.niteurope.com and www.clamir.com.