Thin-film design software keeps up with the times

The demands on software for designing thin-film coatings are shifting significantly in response to new technology development and changing market demands. In some cases thin-film designers are borrowing ideas from other areas of optics, and in other cases changes in thin-film design principles may eventually affect other areas of optics. In a recent interview, Angus Macleod, president and CEO of Thin Film Center Inc. (Tucson, AZ), discussed some of the changes that have taken place in recent years and projected some likely directions for change in the future.

As with much of optics, telecom has provided a major impetus for changes, ranging from units of measure all of the way through to methods of design and manufacture. But other areas, such as the development of liquid-crystal displays, are also generating demands for further development and enhanced software capabilities.

Thin-films for communication

Telecom market applications have brought about a gradual shift over the years in specifications for thin-film from the traditional units of percent reflectance and transmittance over ranges of wavelength (measured in nanometers) to units of decibels over frequency ranges (measured in terahertz). These relatively minor changes in thinking and software are not tremendously significant, Macleod said. But the significance might increase with time if such communication-based units of measure also were to spread to other branches of optics.

Dealing with the dispersive properties of coatings through parameters of distortion in short-pulse systems (such as group delay, group delay dispersion, chromatic dispersion, and third-order dispersion) has demanded more substantial change. It has led to a borrowing of methodology from the discipline of ultrafast lasers and remains an area of active development.

"It's been around for five or six years in the ultrafast field," Macleod said. "But as bit rates go up and channel spacing goes down, suddenly it's important in the communication field as well."

Since the interference process is linear, however, Fourier decomposition can be used to look at the various pulse components and their relative phases.

"We've always thought in terms of spectral decomposition of sources but we've never taken notice of the relative phases of the spectral components," he said. "Now, we have to. And this has meant changes in software."

In the ultrafast field, coating designers are learning how to produce specific values of dispersive parameters, but the magnitude of these values in the communications field presents special difficulties in design. Macleod characterized the situation as one of the big question marks over thin-film filters for very narrow channel spacing.

"We're still to some extent wondering what to do about it," he said. "It may become one of the significant things that decides that thin-film filters are better or worse than arrayed waveguides."

From Holy Grail to commodity

Other areas in which telecom in particular has affected thin-film design software include the design of gain-flattening filters to compensate for variance with wavelength along the gain curves of erbium-doped fiber amplifiers, and the development of narrow-band filters.

A large potential market for the former has generated a lot of interest among designers of thin film who hope to provide a better solution than competing technologies such as fiber Bragg gratings. In the latter case, however, both the advance of technology and the vagaries of the market have dethroned narrow-band filters in just a couple of years from the status of Holy Grail to an overabundant commodity. Currently more than half of the software packages on the market that design coatings enable either automatic or semiautomatic design of narrow-band filters.

"Two years ago, 200-GHz filters were on the cutting edge, and now people are just producing them like hotcakes," Macleod said. "In fact, they've produced too many. So the price has gone down and lots of companies are getting out of the business because it's not nearly as profitable as it was."

Market factors in telecom have also encouraged the development of more-efficient methods of design, synthesis, and manufacture. The traditional method of filter design involves combining well-understood building blocks, such as stacks of quarter-wave layers, and putting them together in various ways to produce the desired characteristics. Another way is to program the desired characteristics into a computer along with algorithms for combining sets of layers, all of which have become feasible with the proliferation of desktop computers. Computer design methods have also lowered traditional barriers to entry into thin-film design, because aspiring designers are finding that they no longer need 10 or 20 years of experience to get up to speed. At the same time, computers are blurring the traditional boundaries between design and manufacture of thin-films.

"We even see some machines coming on the market that are virtually automatic," Macleod said. "You can actually design a coating and just feed it into a machine that makes it. Machine tolerances are not always 100% able to produce just any coating you want. But there have been some very interesting demonstrations of completely automatic design and production."

More leading edges

Not all of the factors inducing new developments in thin-film design software are related to telecom, and several involve leading-edge technologies. For instance, designs for display systems based on liquid-crystal light valves on silicon are requiring special software tools for phase characteristics of coatings at oblique incidence, because they are involved in the leakage of light from one polarization to another, which degrades the blacks in the image.1

In the area of inhomogeneous optical layers that might be used in Rugate filters for laser protection applications, interest by mainstream thin-film optics practitioners and a demand for suitable design software is likely to increase due to the appearance on the market of machines that can produce deliberately inhomogeneous layers based mostly on oxynitride materials.

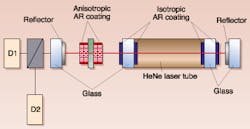

Finally, birefringent crystal material is becoming more common as a substrate for antireflection coatings. Currently, isotropic coatings are normal and are often optimized so that the reflectance for both principal planes of polarization is the same. But researchers have recently reported fabrication of birefringent optical coatings that completely match their birefringent substrates (see figure).2 "Also interference multilayers of birefringent plastic materials with novel variations of performance with angle of incidence are now being manufactured," Macleod said. "We can expect birefringence to have an impact on optical-coating design software."

REFERENCE

- H. S. Kwok et al., Appl. Opt. 39, 168 (2000)

- I. Hodgkinson and Q. Wu, Adv. Mat. 13(12-13), 889 (2001).

Hassaun A. Jones-Bey | Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.