OptiPro aspheric profilometer data analysis software available

OptiTrace aspheric profilometer data analysis software offers multiple profile loading and 3D surface reconstruction for detailed surface analysis of precision optics. Multiple profile loading enables multiple traces from the same optic on one plot, with the ability to overlay scans of iterative correction attempts on top of one another. The 3D surface reconstruction tool allows creation of a 3D surface error map using a 2D contact profilometer.

OptiPro

Ontario, NY

www.optipro.com

More Products

-----

PRESS RELEASE

OptiPro Integrates Powerful New Features to Aspheric Profilometer Data Analysis Software

Features include 3D surface reconstruction, allowing user to produce 3D surface error map with a 2D contact profilometer and work piece rotation

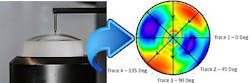

Ontario, NY - OptiPro Systems, LLC continues their dedication to advance precision optics manufacturing technology with the development of new features to their Aspheric Profilometer Data Analysis Software, OptiTrace, enhancing the capabilities of the OptiTrace 5000 contact profilometer (http://www.optipro.com/asphere-measurement.html). Among the new features are multiple profile loading and 3D surface reconstruction, which will yield more detailed surface analysis of precision optics.

With multiple profile loading, the user is now able to load multiple traces from the same optic on one plot. This gives the user the ability to overlay scans of iterative correction attempts on top of one another so that the operator can see where/how the optic is changing. Understanding the progression of optics after each correction run will help companies further optimize their precision optical fabrication processes.

The 3D reconstruction tool allows the operator to create a 3D surface error map using a 2D contact profilometer. Instead of being limited to rotationally symmetric error when correcting with a 2D profile scan, the user can now focus on asymmetric error as well. The user takes the desired number of scans in a bicycle wheel spoke pattern around the optic, rotating it at specific intervals. The algorithm analyzes the data traces and the angles they were taken at and produces a 3D surface error map. The 3D surface error map can then be exported to a variety of common formats for deterministic correction.

"The ability to generate 3D surface error maps gives optical manufacturers a more detailed analysis of what corrections need to be made and greater assurance that the desired surface accuracy is achieved," says Ed Fess, Research and Development Manager at OptiPro. "When it comes to precision optics, having the ideal metrology solution is invaluable because customer satisfaction is riding on your ability to meet specs. The powerful new features to the OptiTrace software helps companies rest assured that they are producing exceptional precision optics."

About OptiPro:

OptiPro is the only U.S. company that designs and builds CNC optical grinding, high speed spherical polishing, sub-aperture polishing, and metrology equipment. OptiPro started out as a reseller and service provider for CNC metalworking equipment over 30 years ago and evolved into an original equipment manufacturer (OEM) of an extensive line of machines for precision optics fabrication. For more information on OptiPro and their entire line of optical fabrication equipment, go to http://www.optipro.com.

-----

Follow us on Twitter

Subscribe now to Laser Focus World magazine; it's free!