Optical trap/tweezers from Laser 2000 traps and images down to 80 nm

Optical trap/tweezers, based on proprietary spatial light modulators, enable optical trapping of microscopic objects using light as a force and computer control for an independent variation of traps in size, position, rotation, and pattern. Features include x-y positioning with >100 µm accuracy and z-adjustment with the microscope objective. It can be set up to trap and image metallic nanoparticles down to 80 nm.

Laser 2000

Munich, Germany

www.laser2000.de

More Products

-----

PRESS RELEASE

Optical Trapping - Optical Tweezing, Stand-Alone System

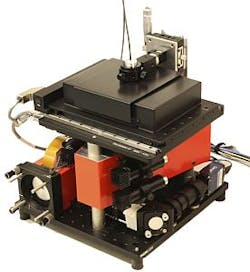

Wessling - Optical trap - optical tweezers to physically manipulate hundreds of microscopic objects in three dimensions (3D) using computer control with graphical user interface including imaging objects in three dimensions (3D) using computer control.

This compact instrument being based on Boulder Nonlinear Systems proprietary Spatial Light Modulators allows scientists to optically trap microscopic objects using light as a force and computer control for an independent variation of traps in size, position, rotation and pattern and more.

The systems is optimized of a high temporal trap stability and user friendly handling with the help of a graphical using interface and a special interface using an iPad for easy handling of individual and even up to 16 traps.

The system includes XY-positioning with a better the 100 µm accuracy and Z- adjustment with the microscope objective. Traps can be moved interactively at >100 Hz. The system can be set up to trap and image metallic nanoparticles down to 80 nm. The setup is based on an inverted microscope with 40x oil immersion objective having an NA of 1.35.

The required 5 W fiber laser with Class 1 safety housing is included in the setup and control.

The CCD-camera enables bright-field, phase-contrast, or dark-field imaging (with appropriate filter). Custom re-imaging arm and interchangeable condenser enables different imaging modes to be selected by flipping in/out components without affecting the trapping optics.

The field of view (FOV) is 12 x 90 µm with a pixel size of 200 nm (depends on microscope objective/camera). The 640 x 480 camera images at 300 frames per second (fps) full-field and up to 3000 fps for one or two beads.

The software includes particle tracking and trap strength measurement options.

The CUBE consists of minimal moving parts to maximize stability (no floating table required). The systems dimensions are 31 x 36 x 36 cm (optical trap) and 50 x 57 x 33 cm (electronics).

The laser and beam path are fully enclosed and allows the use outside of laser labs.

About Laser 2000 GmbH

Since 25 years Laser 2000 is concentrating on the core product areas of Photonics market. Our experts and experienced account managers ensure the best possible attention to your requirements today for the solutions of tomorrow.

Laser 2000 is headquartered in Munich, Germany and operates local offices in all major business areas of the European market. In order to support your application we deliver top-level service and products and meet the highest standard of quality. With an installed base of thousands of applications around the world,

Laser 2000 has shown the ability to provide onsite-support in time.

More information at www.laser2000.de

-----

Follow us on Twitter

Subscribe now to Laser Focus World magazine; it's free!