Optical-coherence microscope images below the skin with a liquid lens

Rochester, NY--University of Rochester optics professor Jannick Rolland has developed an optical technology that combines a liquid lens with optical-coherence microscopy (OCM) to provide unprecedented images under the skin's surface (OCM is a combination of optical coherence tomography with confocal microscopy).

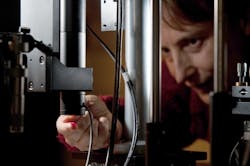

The aim is to detect and examine skin lesions to determine whether they are benign or cancerous without having to cut the suspected tumor out of the skin and analyze it in the lab. Instead, the tip of a roughly one-foot-long cylindrical probe is placed in contact with the tissue and within seconds a clear, high-resolution, 3D image of what lies below the surface emerges.

Rolland presented her findings at the 2011 annual meeting of the American Association for the Advancement of Science in Washington, D.C., on Feb. 19.

"My hope is that, in the future, this technology could remove significant inconvenience and expense from the process of skin lesion diagnosis," says Rolland. "When a patient walks into a clinic with a suspicious mole, for instance, they wouldn't have to have it necessarily surgically cut out of their skin or be forced to have a costly and time-consuming MRI done. Instead, a relatively small, portable device could take an image that will assist in the classification of the lesion right in the doctor's office."

Micron-scale resolution up to 1 mm deep

The device accomplishes this using a liquid-lens setup developed by Rolland and her team. In such a lens, an electrical field around a droplet of water is varied to change the shape of the droplet, and therefore the focus of the lens. This allows the device to take thousands of pictures focused at different depths below the skin's surface. Combining these images creates a fully in-focus image of all the tissue up to 1 mm deep in human skin, which includes important skin-tissue structures. Because the device uses near-IR light instead of ultrasound, the images have a precise, micron-scale resolution (instead of the millimeter-scale resolution of ultrasound).

The process has been successfully tested in in-vivo human skin; several papers on it have been published in peer-reviewed journals. Rolland says that the next step is to start using it in a clinical research environment to assess its ability to discriminate between different types of lesions.

Rolland joined the faculty of the Hajim School of Engineering and Applied Science's Institute of Optics in 2009. She is the Brian J. Thompson Professor of Optical Engineering and is also a professor of biomedical engineering and associate director of the R.E. Hopkins Center for Optical Design and Engineering.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.