Open-source platform advances biomedical-image processing

Madrid, Spain and Cambridge, MA--Ignacio Arganda, a researcher from San Sebastián de los Reyes working for the Massachusetts Institute of Technology (MIT), and his team have implemented Fiji, a software-sharing platform that allows for biomedical-image-processing applications to be shared in order to improve and advance the software.

Fiji, which has enjoyed the voluntary collaboration of some 20 developers from all over the world, is now a de-facto standard that assists laboratories and microscope companies in their development of more-precise products. "All of this in open source," says Arganda.

Built from ImageJ

The platform was built from a previous one called ImageJ, which was well-known in the industry at the time. ImageJ was not an open-source platform but it was publicly accessible. According to Arganda, it had the advantage that any person working in medical imaging could easily create small software applications to resolve their particular problems and then incorporate it into the platform by means of a software plug-in.

Arganda says that this platform became too chaotic with applications of all kinds, some of which were not related to biomedical imaging: it was being used to handle astronomical imaging, in video tracking, and other unrelated uses. "There was a significant lack of control and structure," he notes.

Therefore, "in a spontaneous manner and without any help," this group of researchers decided to create the new open-source platform. "We created a web page organized like Wikipedia where people could contribute and use their knowledge to help others," says Arganda. "To our surprise, it became very popular." According to Arganda, Fiji currently has 127,000 unique visits (20,000 each month).

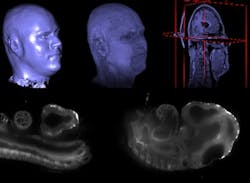

The scientists behind Fiji got in contact with Arganda because of his doctoral thesis. "I was working on a project involving the study of mammary gland development and breast cancer in mice and I had a few tissue samples. I began to develop a program for elastic image alignment that would allow me to create a 3D reconstruction. They expressed their interest and called asking me to collaborate in the platform."

Commercial involvement

Arganda believes that the success of Fiji is also changing the way that biomedical-imaging companies are behaving. These include microscope firms with large laboratories. "These companies recognize the platform as a high-quality standard and they are aware of their two options: either compete or collaborate with Fiji. They can create and maintain their own plug-in that works in the platform and they can then sell them if they become very specific," Arganda says.

"In my case, for example, I was contacted by a microscope company because they were using my elastic-image-alignment program to correct deformations in their microscopes," he says. "They asked me for a specific version of the program, but I had developed it during my thesis so it could not be sold easily. In the end we reached an agreement for its use under the one condition that they would communicate any improvement made so that it could be introduced as open-source and uploaded onto the platform.

"The platform makes you highly visible," he adds. "They offered me the chance to complete a postdoctoral fellowship at Stanford University and MIT because they had access to my code for the elastic alignment software and knew what it was capable of."

Source: http://www.alphagalileo.org/ViewItem.aspx?ItemId=123619&CultureCode=en

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.