Zemax optical design software includes 256 bit algorithm

Zemax optical design software includes Black Box capability. It contains all information needed to trace real rays at a desired field point, wavelength, and conjugate as if the original surfaces and design data were present in the lens data editor. The actual data is encrypted with a 256 bit algorithm so the user cannot see or modify it.

Zemax Development Corp.

Bellevue, WA

[email protected]

-----

PRESS RELEASE

ZEMAX Adds Black-Box Capability to Protect Designers' Intellectual Property

Sharing optical design data can present some difficulties for optical designers and the organizations that employ them.

Although customers, suppliers, external consultants etc. may need to receive ray-traceable data files in order to perform their work, providing this data exposes the original designer's intellectual property. First order methods, like paraxial surfaces and ABCD matrices are fine for providing data like pupil sizes and locations, or image location and magnification, but do not provide any aberration data and so are not useful for designing subsequent or prior optical components, or for assessing image quality.

The ZEMAX black box, however, contains all the information needed to trace real rays at whatever field point, wavelength and conjugate is desired, exactly as if the original surfaces and design data were present in the Lens Data Editor. The detailed data is actually hidden inside the Black Box, and the user cannot see or modify any of the data contained within the hidden Black Box section. The data is encrypted using a 256-bit algorithm.

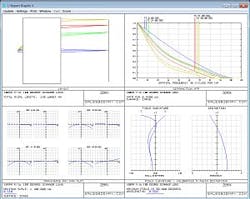

The attached screenshots shows a 100-degree scan lens as a Black Box surface only, and the Black Box with some typical ray-trace data. The data is identical to that produced by the native lens design, but the Black Box keeps the design data secret.