A smart sensor is a sensor with processing and communications capabilities. Smart sensors are key to the success of the Internet of Things (IoT), the network that connects physical devices to collect and exchange data. For the IoT, sensors are used for everything from monitoring and gathering information to natural disaster relief to healthcare to smart homes and industry.

MEMS in smart sensors

There are several elements of smart sensors. These include:

- Sensing element

- Amplification

- Hardware

- Data conversion

- Software

- Data communication

The sensing element often incorporates microelectromechanical systems (MEMS) when used for applications such as smart homes, biosensors, chemosensors, smart microphones, and more.

Smart sensor design with OpticStudio

Optical design software can simplify smart sensor design. For example, OpticStudio from Zemax is two software packages in one: an optical design package and an illumination design package. The optical package allows fast and efficient design of imaging systems, including camera lenses and complex freeform systems. The illumination package accurately simulates light sources, including camera flashes and infrared lasers. Both packages are seamlessly integrated into one, intuitive user interface.

This means that OpticStudio can be used to design all optical components in active and passive sensor systems. Active sensors include a light source to illuminate an area of interest, and measure the reflected signal, while passive sensors measure energy from other light sources, like the sun, or ambient lighting. Both can be used in IoT applications.

OpticStudio has capabilities specifically for the design of optical color sensors, which are used in a wide variety of industries and applications, ranging from monitoring color consistency in textile production to monitoring algae blooms. Color sensors may be active sensors, requiring LED sources (white, or red/blue/green) to illuminate the objects under test, or they may be passive sensors, recognizing the wavelengths of self-luminous objects.

Optical proximity sensors are active sensors that detect the distance, absence, or presence of an object. High sensitivity proximity sensors are used in astronomy, spectroscopy, night vision equipment, and laser range finding. For example, there is a lidar camera on the Google car, which uses arrays of 32 or 64 lasers to measure distances and generate a 3D map.

Movement and presence sensors are active sensors that detect when an object interrupts a light beam. For example, smartwatches use these sensors to measure the wearer’s heartbeat. With each cardiac cycle the heart pumps blood into the periphery, distending the arteries and arterioles in the subcutaneous tissue, causing a small change in volume. This change is detected by illuminating the skin with the light from an LED, and then measured.

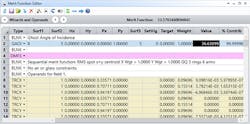

In sensor-based imaging, total internal reflection from ghost reflections is often a significant issue. With the new Ghost Angle of Incidence operand in OpticStudio, engineers can now control these during design in sequential mode.

This new optimization operand calculates the angle of incidence of a ray at any surface, after a double-bounce ghost reflection. The ghost system that is traced is the same as if it was created with the Ghost Focus Generator tool.

eGuide: How to perform stray light analysis

Stray light analysis is a critical step when designing smart sensors. Get the guide to learn how to analyze stray light in OpticStudio using the Filter string and more.