Menlo fiber-optic timing system advances relativistic geodesy

The Geodetic Observatory Wettzell, located atop Wagnerberg mountain in the Bavarian Forest of Germany, gathers data used to quantify global geoscience coordinate reference systems to perform important measurements such as very large baseline interferometry (VLBI), continental drift movements, and sea level rise, as well as to perform ordinary surveying and global navigation tasks.

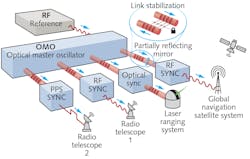

To define a point of reference in time and space at the observatory by disseminating the timing signal from a master clock to the different measuring stations of the observatory such as radio telescopes, laser telescopes, and local measuring systems, Menlo Systems (Martinsried, Germany) developed a complete drift-free fiber-optic timing distribution system. Based on processing optical signals (or pulse frequencies), the timing system allows synchronization without disturbances over large distances with ultrahigh accuracy.

The facility’s central clock system consists of a hydrogen maser that is compared to cesium atomic clocks for the most precise and stable clock signal. It serves as the reference for the stabilized optical master oscillator—the core of the timing distribution system provided by Menlo. The oscillator, an ultrastable erbium-doped fiber laser, emits femtosecond pulses at a 1560 nm wavelength that are sent via dispersion-compensated optical fiber links to the client stations with minimal phase noise and drift, ensuring <10 fs deviation from the master clock at the end of the 400 m fiber link.At the system backends, the individual clients are synchronized to the stable optical signal. At Wettzell, the optical signal is transformed into a 1 pulse per second (pps) clock signal that is coherent with respect to the observatory’s master maser. In other scenarios, the clock signal might be delivered as an optical signal of a different laser wavelength or as an RF signal. Depending on the requirement, the synchronization at the back end is customized accordingly. Synchronization of the facility’s measurement apparatus to the master allows for a global time reference by relaying the signal through satellite systems, advancing relativistic geodesy, and paving the way for testing the principles of the theory of relativity in the future. Reference: http://bit.ly/wettzell.

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.