Microscopy: Imaging system ensures proper coating thickness

Manufacturers of coated steel products have two main production costs—steel and coating. Too much coating impacts profitability, while not enough may lead to potential warranty claims. Understanding this, DJH Designs (Oakville, ON, Canada), a test-equipment supplier, partnered with systems integrator Skye Automation (Stirling, ON, Canada) to develop a means to control coating thickness on steel.1

“Quality checks such as color, gloss, solvent resistance, and coating thickness require cut samples off the line,” explains John Henderson, president of DJH Designs. “The system measures very thin film coatings, from 0.5 µm up to about 25 µm.”

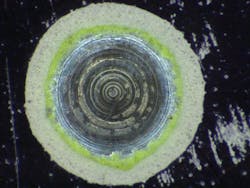

Before measurement, an operator bores into a metal sample through the coating and into the top surface of the substrate. After the operator focuses a microscope custom-built by DJH Designs over the metal sample, the system automatically captures multiple images at different exposures and computationally creates a high-dynamic-range (HDR) image (see figure).

“The system measures the diameter of multiple layers of coating and craters to accurately measure the thickness of the coating,” says Skye Gorter, president of Skye Automation, which provided the machine-vision integration and software for the microscope-based testing system. “Lighting control through the computer enables the system to maintain consistency based on the f-stop position of the microscope variable to its position—as lighting intensity through the full range of the microscope positions must be sustained.”

The microscope includes a camera with a 2 Mpixel CCD image sensor for capturing full-frame images at 27 fps. An integrated fiber-optic white ring light provides illumination for the microscope-based system.

“Because inspected samples can be a variety of colors, a camera capable of providing excellent balance of the color channels according to their spectral response provides optimal contrast regardless of the color combination. Otherwise, using a color channel gain becomes necessary for calibration of the specific channels,” says Gorter. “Edge-detection tools applied on a 16-bit high-dynamic-range grayscale image are possible due to the equivalent quantum efficiency of the RGB response of the camera.”

After creating the HD image, the software determines the proper measurement solution, first performing a measurement to find the leading edge of the top coat. Once found, these positions determine the next inspection. Then the imaging software calculates the difference between these positions using the number of pixels, based on the camera resolution and the relative position of the microscope, because the crater size changes with the thickness of the coating. The software reads the encoder position of the microscope and calculates field of view using an advanced calibration routine based on a number of stops through the full range, explains Gorter.

“Once the Vpro software calculates the field of view, a polynomial regression algorithm is used to determine a best-fit curve for the data, enabling the calculation of the exact thickness of the coating based on 360 data points around the perimeter of the metal sample,” Gorter says.

Finally, the system converts pixels to real-world units such as microns. The FOV changes depending on the microscope position as monitored by the encoder. As the field of view changes, the software adjusts for the dimensional change of the image, according to Gorter. From a captured image and an encoder reference, the software calculates the thickness based on these parameters to an accuracy of 0.1 µm.

In terms of potential savings for application coating companies offered by such a system, based on an average industrial coating with a cost of $6.75 per liter, and using a conservative consumption of approximately eight million liters of paint per year, when breaking down the cost of coating per liter, it works out that every micron of coating put down accounts for approximately $1 million, according to Henderson.

“If the system saves even half a micron of coating each year, this means half a million dollars savings. On the other hand, if a company has a 20 µm specification, an upper limit of 22, and lower limit of 18; companies may try to run toward the bottom of that spec to reduce the amount of paint consumed,” he says. “Anything under that spec, however, opens companies up to huge warranty claims. One rejection from a newly installed system pays for the cost of the equipment itself.”

REFERENCE

1. J. Carroll, "Machine vision system measures paint coating thickness on steel products," Vision Systems Design, 24, 8, 20–22 (Sep. 2019).

About the Author

James Carroll

Editor in Chief, Vision Systems Design

James Carroll is the Editor in Chief for Vision Systems Design, a sister publication of Laser Focus World. James, who joined Vision Systems Design in 2013, has covered the machine vision and imaging from numerous angles, including application stories, industry news, market updates, and new products.