Rice’s RAMBO-II spectrometer will have stronger magnets, wider range of lasers

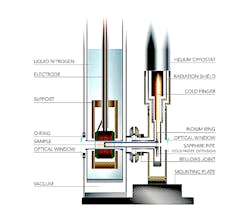

RAMBO, short for Rice Advanced Magnet with Broadband Optics, is a unique instrument that Rice University (Houston, TX) engineer, physicist, and materials scientist Junichiro Kono created in 2013 in collaboration with colleagues in Japan. RAMBO lets researchers use a wide spectrum of laser pulses to examine the behavior of materials that are simultaneously cooled near absolute zero and subjected to a massive pulse of magnetic energy. Cooled with both liquid helium and liquid nitrogen, the entire device fits atop a single table in Kono’s lab.

Armed with a $1.5 million grant from the National Science Foundation, Kono and collaborators are now preparing to create RAMBO-II, a successor capable of producing stronger magnetic fields and probing samples with an even broader spectrum of intense laser pulses.

The upgrade project teams Kono with magnet designer and builder Hiroyuki Nojiri, the creator of RAMBO’s original 30-tesla pulse magnet, a device no larger than a golf ball. For RAMBO-II, Nojiri’s team at the Institute for Materials Research at Tohoku University in Sendai, Japan, will create three 50-tesla pulse magnets that are about the same size as the original 30-tesla model.

“Magneto-optical spectroscopy experiments can be conducted in strong magnetic fields at many facilities, but the magnets used in those facilities are extremely bulky and have no windows to directly access samples with a laser,” says Andrey Baydin, a postdoctoral researcher in Kono’s laboratory and an expert in high-field spectroscopy experiments. “Instead, light must be sent down long optical fibers before it reaches the sample.”

The dispersion in optical fibers elongates ultrashort laser pulses, making certain kinds of spectroscopy impossible. Baydin says optical fibers aren’t necessary with RAMBO because Nojiri’s magnets are designed to allow several lasers to be directed at samples inside the magnet. “The size and shape of the magnets is key to coupling strong magnetic fields and ultrashort laser pulses covering a broad range of spectrum from the terahertz to the extreme ultraviolet,” Baydin adds.

The first of Nojiri’s 50-tesla magnets will be installed before the end of 2020 in the original RAMBO, which is equipped for terahertz spectroscopy. Nojiri’s other two magnets will be used in RAMBO-II instruments in the laboratories of Rice physicist Ming Yi and Rice materials scientist Hanyu Zhu. In Yi’s lab, RAMBO-II will be outfitted for angle-resolved photoemission spectroscopy, and in Zhu’s lab the platform will use extreme ultraviolet (EUV) spectroscopy. Yi, Zhu and Rice’s Aditya Mohite are coprincipal investigators on the grant.

Kono says RAMBO’s unconventional coupling of magnetism and optics has allowed his group and others, including a number of visiting scientists, to produce new scientific knowledge. RAMBO-II, with its added capabilities, is expected to produce additional breakthroughs that advance the frontiers of materials physics and chemistry. “RAMBO-II will revolutionize optical studies of condensed matter under extreme conditions,” Kono notes.

Source: http://news.rice.edu/2020/08/24/rices-rambo-ii-a-sequel-better-than-the-original-2/

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.