Microreflector boosts Raman signal in 3D SERS chip

Widely used for detection of biological molecules and other substances, surface-enhanced Raman spectroscopy (SERS) uses nanostructures (often silver or gold nanoparticles) on a surface to enhance Raman scattering and therefore detection efficiency. The extremely sensitive technique can, of course, be made even more sensitive by increasing the incident light intensity. Researchers at Chongqing University (Chongqing, China), Chinese Academy of Sciences (Shanghai, China), and the Sichuan University of Arts and Science (Dazhou, China) have developed a simple way to do just this by adding a 100-μm-deep inverted pyramid microreflector (IPMR), coated with a gold film, to the active substrate, resulting in a threefold experimental signal intensity boost.

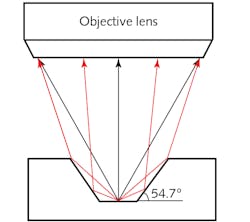

The researchers first modeled the microreflector’s performance using the ray optics module of COMSOL Multiphysics software (COMSOL; Burlington, MA), choosing a reflector angle of 54.7° because it is the angle between the (111) plane and the (100) plane of monocrystalline silicon, and arises naturally from etching. The electric-field distribution was also modeled using the wave-optics module of COMSOL Multiphysics 5.4. The SERS substrate had on average four layers of 50-nm-diameter silver nanoparticles; the incident light had a 785 nm wavelength. Simulation results showed that adding the gold film doubled the Raman intensity, and adding the microreflector approximately doubled the Raman intensity again.

An experimental substrate with a microreflector was fabricated via wet etching, and a gold reflective layer then deposited on the structure. Measurements of the device showed some enhancement of Raman intensity, but not the twofold predicted by simulation—more like about 1.5X. Four layers of silver nanoparticles were then added and Rhodamine 6G (R6G) used as the probe molecule for SERS testing, producing the 3X total enhancement. Improvements to the fabrication and bonding processes should raise the performance of the microreflector nearer to the simulated results, say the researchers. Reference: Y. Feng et al., Opt. Express (2020); https://doi.org/10.1364/oe.410966.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.