Advances in DMD-based spectrometers benefit industry and medicine

Ongoing developments in industries such as precision agriculture and healthcare point-of-care (POC) testing have increased the demand for compact, low-cost, and ruggedized spectral analyzers. For applications using the near-infrared (near-IR) spectrum from 900 to 2500 nm, this is particularly challenging since spectrometers for this wavelength range tend to be much more expensive than devices for the visible wavelength range. This article will show how advances in spectrometers based on digital micromirror devices (DMDs) can address cost, compactness, and stability issues.

DMDs in spectrometers

DMD technology was introduced in the 1990s and used inside meeting-room projectors and large-format cinema projectors.1 The early DMDs were naturally developed for the visible wavelength range from 400 to 750 nm. However, the technology can also be used outside this range, and has for example been adopted in optical switches at 1550 nm for telecommunications networks.2 In the case of spectroscopy, DMDs are mostly used in the near-IR range due to the cost benefit they offer in this range.

A DMD chip consists of a large number of micromirrors manufactured as microelectromechanical structures (MEMS) in silicon and coated with a metal coating for high reflectance. The mirrors are typically a few microns wide and arranged in a two-dimensional pattern (see Fig. 1). The mirrors can be in three distinct angular positions only, and this is one of the key strengths of this technology. The angular position of each mirror is extremely precise and repeatable, even after thousands of movements, making the technology very robust and therefore well suited for industrial applications in spectroscopy.

Figure 2 shows schematically the key optical building blocks required in a DMD-based spectrometer. The collection optics are used to collect a broadband spectrum of light from a light source (like a halogen lamp). The dispersive element, which can be a prism or a diffraction grating, is used to separate the wavelengths of the spectrum spatially, and the focusing optics are used to focus each wavelength on a specific column of mirrors of the DMD array. By setting the mirrors appropriately, a single wavelength can be selected and sent to a photodetector by the delivery optics.

The sample to be analyzed can be inserted either before the collection optics (predispersive configuration) or after the delivery optics (postdispersive configuration), as indicated by the dashed sample locations in Figure 2.One complication in the design of a good, high-throughput DMD spectrometer is that the DMD array acts as a blazed grating. This is particularly important for longer wavelengths where the mirror-to-mirror distance becomes comparable to the wavelength of light. The strengths of the 1st and 2nd order diffraction can easily be stronger than the specular (0 order) reflection from the mirror surfaces, and therefore the delivery optics in Figure 2 must be designed to capture as much of these higher orders as possible.

A typical compact spectrometer for industrial applications is based on a diffraction grating and an array of photodiodes in which each photodiode detects the light intensity at a separate wavelength. For the near-IR range, it is not feasible to use low-cost silicon photodiode arrays since silicon is transparent above 1100 nm. Therefore, more expensive detector materials like indium gallium arsenide (InGaAs) must be used. This makes the detector a determining part of the overall unit cost.

In a DMD-based spectrometer, the expensive diode array is replaced by the DMD chip and a single InGaAs photodiode. The latter combination can be 5–10X lower in cost than the former, hence a DMD-based spectrometer can offer a lower-cost alternative to diode-array spectrometers.

Compact design

The two key elements in obtaining a compact DMD-based spectrometer design are short focal lengths for the optics and a folded optical path using retroreflective design. The focal lengths of the various optics used in the DMD spectrometer basically determine the distance between the optical elements, and thereby the total length of the device. Minimizing the focal lengths therefore minimizes the overall length of the spectrometer. For the delivery and collection optics, however, the focal length cannot be chosen arbitrarily small, since the field of view (FOV) of the sample and detector needs to be taken into consideration, as well as the actual spot size required on the sample to obtain meaningful data.

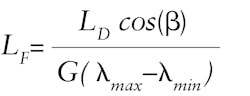

The focal length of the focusing optics in Figure 2 can be minimized by proper choice of diffraction grating and DMD array. The focal length of the focusing optics can be approximated quite well with the following simple formula:

where LD is the length of the DMD array, β is the diffraction angle, G is the grating groove density, and λmax and λmin are the longest and shortest wavelengths in the spectrum. As can be seen from the equation, the focal length is minimized when the grating groove density is chosen as high as possible and the length of the DMD array as small as possible.

DMD arrays with mirror sizes of only 5 μm with 854 mirrors across the array have become available during the past few years, which enables a LD on the order of 4.5 mm. The wavelength range is generally determined by the sample you want to analyze, so λmax and λmin cannot be chosen freely to minimize size. Gratings with high groove density have traditionally had the drawback that they were either not very efficient or strongly polarization-dependent.3 However, developments in transmission-grating technology have enabled gratings with high groove density as well as high and polarization-insensitive diffraction efficiency.

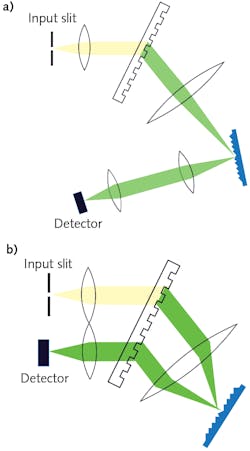

From Figure 2, it can be seen that the instrument requires a collection of optics before the DMD array and a collection of optics after the DMD array. This obviously requires space for the lenses (see Fig. 3a). However, using the retroreflective design shown in Figure 3b, a much more compact spectrometer is obtained. This can be done if the grating is transmissive with very little loss and the collection and delivery optics are identical.Stability

As mentioned in the introduction, the micromirrors can only be in three distinct angular positions. So, even though the mirrors do move during a wavelength-range scan, they are extremely accurate and repeatable and for this reason very stable against, for instance, external vibrations and temperature changes. Furthermore, the use of transmission optics before and after the DMD array rather than reflection optics also provides very low sensitivity to such external influences.

In conclusion, DMD-based spectrometers for the near-IR wavelength range can be more cost-efficient than diode-array spectrometers because the DMD enables use of a single lower-cost detector. By designing around a transmission grating with high groove density in a retroreflective configuration, it has been shown how a compact unit can be built. DMD-based spectrometers can be very stable against external environmental influences due to the DMD array itself, as well as the use of transmissive optics rather than reflective optics.

REFERENCES

1. L. J. Hornbeck, Proc. Dig. IEEE/LEOS Summer Topical Meetings, 7–8 (1996).

2. L. A. Yoder et al., Proc. SPIE, 4457, 54–61 (Nov. 2001); doi:10.1117/12.447760.

3. C. Palmer, Diffraction Grating Handbook, 8th ed., MKS Newport (2020).

Thomas Rasmussen | VP Business Development, Sales, and Marketing at Ibsen Photonics

Thomas Rasmussen is VP Business Development, Sales, and Marketing at Ibsen Photonics (Farum, Denmark).