3D-printed spectrometer has a 100 × 100 square micron footprint

Femtosecond direct laser writing as a 3D printing technology has been one of the key building blocks for miniaturization in modern times. It is now possible to create monolithic and nearly perfectly aligned freeform optical systems on almost-arbitrary substrates such as image sensors or optical fibers. Simultaneously, the miniaturization of spectroscopic measurement devices has been advanced—for instance, based on quantum-dot or nanowire technology. These are based on computational approaches, which have the drawback of being calibration-sensitive and require complex reconstruction algorithms.

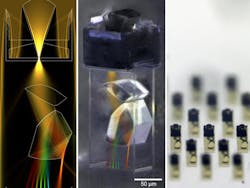

Now, a team of scientists from the University of Stuttgart (Germany) has demonstrated an angle-insensitive 3D-printed miniature spectrometer with a direct separated spatial-spectral response; the instrument has a volume of less than 100 × 100 × 300 μm3. The design is based on a classical grating spectrometer and was fabricated via two-photon direct laser writing combined with an inkjet process. Its tailored and chirped high-frequency grating enables strongly dispersive behavior. The miniature spectrometer has a wavelength range from 490 nm to 690 nm and a spectral resolution of 9.2 ± 1.1 nm at 532 nm and 17.8 nm ± 1.7 nm at a wavelength of 633 nm. (The figure shows a wave-optical simulation of the spectrometer at left, a microscope image of the fabricated spectrometer at center overlaid with the intensity distribution from the simulation, and an array of array of fabricated spectrometers at right.)

“Our spectrometer could be fabricated directly on a miniature image sensor as the tip of a distal chip endoscope,” says researcher Andrea Toulouse. “This way, regions in the human body could be examined with extremely high bending radii that were not accessible before. It could also be an interesting approach for hyperspectral imaging where the spectrometer would be used as a unit cell (macro pixel). The redistribution of spectral energy instead of high-loss Fabry-Perot filtering could thus enable highly efficient hyperspectral imaging sensors. The ever-growing world population could benefit from such a camera if it was used for spectral mapping in precision farming, for instance.” Reference: A. Toulouse et al., Light Adv. Manuf. (2021); https://doi.org/10.37188/lam.2021.002.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.