Gas sensor leads toward the future of home building and automation

Most people spend a good portion of their time indoors, where they are unknowingly exposed to a concentration of pollutants—from ambient air and fragrances to food quality and general human activity—that is sometimes higher than what is found outside. This could potentially have a profound effect on human health and wellbeing, but traditionally it has been difficult to monitor such pollutants indoors. Now, a new gas sensor could help make those indoor settings safer and healthier.

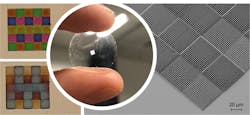

Developed by a team from Trinity College Dublin and AMBER (SFI Research Center for Advanced Materials and Bioengineering Research), this 3D-printed, color-changing, microscopic sensor can detect solvent vapors in the air and can be monitored in real time via connected, low-cost devices for homes or integrated into wearable devices used for monitoring human health.

The researchers employed direct laser-writing (DLW) to focus on extremely small areas and create “tiny structures in three dimensions from the soft polymers” they have developed in the lab. The study focuses particularly on the design, modeling, and fabrication of different structures that can respond to light, heat, and humidity to create systems that can “truly recreate the vividness, stealth response, and camouflaging ability found in nature,” says Louise Bradley, a professor of photonics at Trinity College Dublin who participated in the study.

According to the researchers, the new gas sensors “could play an enormous role in the development of a domestic environmental monitoring ecosystem. This could ensure that health and wellbeing monitoring become central to the future of home building and automation.” Reference: C. Delaney et al., J. Mater. Chem. C, 9, 11674–11678 (2021).

Justine Murphy | Multimedia Director, Digital Infrastructure

Justine Murphy is the multimedia director for Endeavor Business Media's Digital Infrastructure Group. She is a multiple award-winning writer and editor with more 20 years of experience in newspaper publishing as well as public relations, marketing, and communications. For nearly 10 years, she has covered all facets of the optics and photonics industry as an editor, writer, web news anchor, and podcast host for an internationally reaching magazine publishing company. Her work has earned accolades from the New England Press Association as well as the SIIA/Jesse H. Neal Awards. She received a B.A. from the Massachusetts College of Liberal Arts.