Point-of-need sensors get a boost from hybrid SERS partnership

Surface-enhanced Raman spectroscopy (SERS) is a rapid growth area with the potential to enable new point-of-need sensor technology due to its superior sensitivity and wide applicability.

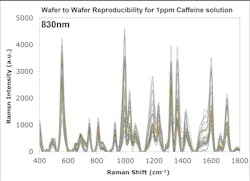

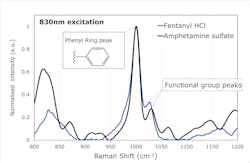

With this in mind, Morrisville, NC-based Wasatch Photonics (Morrisville, NC) entered into a strategic partnership to evaluate a novel nanoparticle SERS substrate developed by Nikalyte (Bicester, U.K.). The results so far are promising, especially for detection of trace analytes such as caffeine, ibuprofen, and fentanyl (with less than parts-per-million sensitivity)—representing exciting commercial potential for use in homeland security, forensics, food safety, and healthcare screening (see Figs. 1 and 2).The partnership between the two companies empowers each party to focus entirely on its core competencies. For Wasatch, this means exploring the problems it can solve from an instrumentation standpoint. It also allows Nikalyte to solve problems and make a more sensitive, reproducible substrate based upon the physics of its deposition technique.

“Having people focusing on their core competencies around a common goal is key to the future of the photonics industry. The interconnection of hardware and sensors is going to be very interesting for what’s next in spectroscopy,” says Wasatch Photonics CEO David Creasey. “This is a marriage of our technologies, which makes it quite comfortable because we’re not trying to tread on each other’s toes. We actually need the other party to succeed.”

Why not wet?

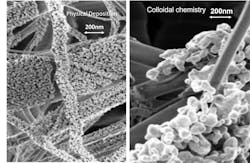

Ease of use is crucial in Raman, which has been a plus for traditional chemical-based substrates. Yet, while the conventional wet-deposited SERS substrates offer convenient sample preparation in that they use a sensor pad mounted to a microscope slide, they often display significant spatial inhomogeneities, resulting in low signal reproducibility. SERS using colloidal gold nanoparticles within aqueous solution, in contrast, yields very reproducible signals, but requires handling of solutions not conducive to field use by non-experts.

Nikalyte’s substrate deftly addresses barriers that previously limited widespread adoption of SERS. Its approach is unique in that it uses gold nanoparticles generated and deposited within a vacuum, ensuring they are ultra-pure and highly uniformly distributed (see Fig. 3). “We have developed a unique technique to make nanomaterials with a specific focus on enhancing Raman signals,” says Nikalyte CEO Alistair Kean. “Our method provides more ideal deposition or coverage of nanoparticles that can be applied to things like cell binding, catalysis, and electrochemistry.”As no chemicals are used in the synthesis of the nanoparticles, the SERS substrates are free of contamination, improving sensitivity and specificity. Cost-effective scalability is a key focus, with test substrates available for less than $10 USD.

Being able to tailor the specificity via physics, rather than wet chemistry, allows for a greater degree of specificity unaligned to a molecule of interest you’re trying to detect. “It also allows tremendous detection in multiplexing, where different wavelengths on the same substrate may give you different capabilities in terms of modality in the sense of getting much more information,” says Creasey.

There is tremendous versatility in this approach because it essentially functionalizes nanoparticles to look for a particular protein or biomolecule. As such, it’s useable for bacteria detection or biomarkers indicative of disease or damage to the body.

“Once you have the technique for detection (the nanoparticles), the right low-cost instruments can reproducibly give you the answers, and you can apply it in a tremendous number of ways,” says Kean.

Looking beyond sensitivity

Wasatch is trying to solve and develop enabling capabilities in Raman around four or five key areas, including the sensitivity of throughput.

“Our optical engineers have improved spectrometer throughput considerably using low f-number, high-efficiency transmissive optical designs, but that only takes you so far,” says Creasey. “Partnering with a SERS company like Nikalyte provides us with further improvements in sensitivity and an interface to the right instrumentation, for the right species of interest.”

Of course, the real issue is not sensitivity—it’s reproducibility. After all, it’s one thing to take a measurement and get a great signal, but if you can’t reproduce it the applicability in real-world applications is limited.

“We are really interested in taking Raman from a traditional white powder, forensic, or hazmat application to a more biological or life sciences arena,” says Creasey. “We’re going to be involved in measuring analytes at low concentrations, for applications where the results are particularly important and may determine a course of treatment for a patient. Therefore, having reproducible and trustworthy data is very compelling.”

The great thing about SERS is the ability to hugely amplify signals, explains Kean. “Unfortunately, this means you can amplify everything else as well. For instance, if there’s something that changes slightly it can give you essentially a varying measurement, so reproducibility really is key.”

With chemically made nanomaterials, there are a lot of unknowns and empirical processes. If something changes, it means going back and changing the temperature or other fabrication parameters.

“We can use our knowledge of physics to control the formation of these nanoparticles and essentially count the number of atoms in each nanoparticle,” says Kean. “By controlling the size of the nanoparticle and allowing uniform and reproducible deposition or loading of those nanoparticles, repeatability between samples is feasible. If things vary, we control the parameter space. Our technique gives us the best fighting chance of achieving high reproducibility.”

Ongoing evolution

During the last couple of years, the attention on COVID-19 has generated renewed interest in SERS testing and its ability to provide specificity for certain proteins and chemicals of interest. Carrying this forward, the growth potential within the life sciences is intriguing—anything from disease detection to identifying harm and damage being done to organs.

“We’re not going to solve all the world’s ills, but with enhanced specificity we can help pull out abnormal from normal biochemical signatures,” says Creasey.

His goal is to see a compact Raman instrument in the back of every police car, ambulance, and hospital bedside. “Having accurate point-of-care measurements is vital. The competing technologies not only are expensive, but typically involve some level of chemical processing, which means it can take quite a while for results to come back,” he says. “In the interim time, it’s not always easy to work out how to treat an incoming patient as they come into the emergency room. It’s our goal to provide the enabling optical engine that makes point-of-care biological measurements with Raman and SERS feasible, and we see academia and industry poised to bring those applications to life.”

About the Author

Peter Fretty

Market Leader, Digital Infrastructure

Peter Fretty began his role as the Market Leader, Digital Infrastructure in September 2024. He also serves as Group Editorial Director for Laser Focus World and Vision Systems Design, and previously served as Editor in Chief of Laser Focus World from October 2021 to June 2023. Prior to that, he was Technology Editor for IndustryWeek for two years.

As a highly experienced journalist, he has regularly covered advances in manufacturing, information technology, and software. He has written thousands of feature articles, cover stories, and white papers for an assortment of trade journals, business publications, and consumer magazines.