Raman spectroscopy—a noncontact, nondestructive molecular fingerprinting technique—provides chemical information comparable to Fourier transform infrared (FTIR), yet without interference from water and with little-to-no sample preparation. Understanding of this powerful technique has increased over the last 10 to 20 years, bringing with it rapid growth in the applications of Raman spectroscopy to real-world problems.

Raman has already revolutionized quality control in pharma and improved security for first responders. It is now poised to have a similar impact on healthcare, food, and many other areas, thanks to its ability to extract meaningful answers from complex samples. The rapid, noninvasive, and increasingly compact nature of Raman measurements are also ideal for point-of-use and mobile settings. Medical diagnostics, environmental monitoring, and quality and process control in the food chain, energy industry, and manufacturing can all benefit from Raman’s ability to provide sensitive and specific answers to difficult questions.

An essential part of Raman’s leap from the lab to the field, the clinic, and industry has been the availability of compact, portable instruments with access to raw data required to develop advanced data analysis methods custom to each application. As the number of compact Raman spectrometers and systems on the market increases, each with their own claims, it can be daunting to identify which instrument and provider is the best fit for your needs.

Raman spectrometers: where portable fits

A good portable Raman spectrometer bridges the gap between handheld and benchtop Raman spectroscopy. It enables new point-of-use applications in medicine and industry by providing high sensitivity and dependable answers in a compact, cost-effective footprint. These qualities are important to both researchers and OEM instrument developers, particularly for applied R&D and commercialization of new technologies.

Portable Raman spectrometers owe their genesis to benchtop Raman systems—the gold standard in the lab, and the starting point to demonstrate proof-of-concept for new Raman applications. Benchtop Raman systems often feature sophisticated optical interfaces for sample positioning and/or imaging, high-end detectors, and multiple excitation wavelengths to provide the greatest flexibility for research. They come with advanced software that automates signal acquisition and processing, but can hamper access to raw data or development of custom software.

Once proof-of-concept is complete, a compact Raman spectrometer allows the user to streamline and configure a Raman system to their specific application—reducing size, weight, complexity, and cost in the process. If designed with an integrated excitation laser, it becomes truly portable (i.e., small and robust enough to be easily moved from one location to another) with full system control via software. Portable Raman spectrometers are offered at a variety of wavelengths, with a flexible or integrated probe, and are typically operated via a laptop or tablet. Such devices are an excellent choice for applied research, onsite measurements, and for integration into larger, application-specific instruments by original equipment manufacturers (OEMs).

In contrast, handheld Raman instruments are designed for use in the field by nonexperts to deliver definitive identification of a substance upon point-and-click operation. They integrate a single-wavelength Raman system and sampling optics, data processing, and a display screen/user interface into a lightweight, battery-operated unit that is robust enough for use by first responders and in manufacturing environments. They deliver rapid and reliable answers, dependent on the libraries installed. Handheld Raman instruments seldom offer access to raw data, and configurability is limited to the sampling accessories provided.

The final option is smartphone-based Raman spectrometers, which can seem very appealing but often lack the resolution and sensitivity needed for anything but the most basic Raman measurements. An optical resolution of 6 to 15 cm-1 full-width half-maximum (FWHM) is typically needed for Raman spectroscopy, depending on the application.

Sensitivity: The key to specificity and speed

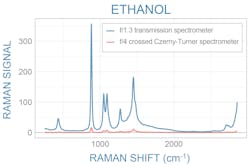

Raman is a low-light technique, which makes every photon precious. A general-purpose compact spectrometer may not have the sensitivity needed to capture a sufficient Raman signal without accumulating excess background noise. The ideal portable Raman spectrometer must capture as much light as possible, then disperse and detect it with high efficiency. One particularly effective Raman spectrometer design uses a low f/# (high NA) input to increase light collection, together with transmission gratings and custom optics to achieve diffraction-limited optical performance. This combination yields a high throughput optical bench able to collect more Raman signal in a shorter period of time. The result is cleaner spectra, better signal-to-noise, lower limits of detection, and faster back-to-back measurements (see Fig. 1). A portable Raman spectrometer designed for maximum sensitivity can measure even low concentrations and weak Raman emitters effectively.

Reliability: The foundation of dependable answers

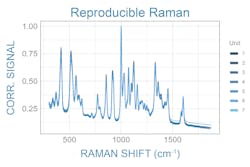

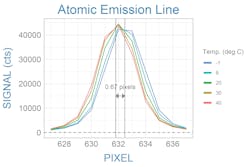

A portable Raman spectrometer needs to perform reliably in a variety of different use-case environments, providing consistent spectral data from one day to the next—independent of changes in temperature and movement. Since analysis of Raman spectra often involves matching to a library or use of chemometric models, greater reproducibility across all instruments yields greater confidence in the classification or match obtained, and fewer indefinite results.

Reliability and reproducibility are particularly important for application-specific instrument developers. These OEMs should look for a spectrometer provider who offers high unit-to-unit consistency in combination with the appropriate wavelength, wavenumber, and spectral response calibrations and standards needed to ensure highly repeatable spectra (see Fig. 2).Configurability: Essential in a streamlined system

A small footprint shouldn’t mean limited options. The configuration of a portable Raman spectrometer influences the strength and quality of its spectra, as well as its practical fit for each application or use-case. To help find the optimum design for your application, look for a supplier that offers:

Multiple Raman wavelengths. This allows you to find the best excitation wavelength to balance signal strength and background fluorescence, thereby improving signal-to-noise.

Models with an integrated excitation laser. This approach reduces system size and cost, while simplifying laser control and cabling.

Spectral range options. Many applications need only the fingerprint region for identification (<1800 cm-1), while others gain key information from an extended range, covering more functional groups (<3600 cm-1).A choice of detector and cooling level. This allows you to balance cost, dark noise, power draw, and size based on your signal level and operating conditions.

Flexible sample coupling options. Being able to switch between solids and liquids makes a system more versatile, as does a fiber-optic Raman probe with a user-interchangeable tip.

OEM module options. Availability of a streamlined, equivalent module for integration into an application-specific instrument can accelerate product development significantly and reduce risk.

A good Raman provider will understand the influence and interplay of each of these factors and can advise on the best match to your application. They should be able to provide spectra that are representative of either your sample or standard compounds you have worked with—or offer a demo or sample measurements to help determine the best configuration for your needs.

Ease of use: A force multiplier for any project

Good products are easy to use, and a portable Raman spectrometer should be no different. Look for Raman-specific software that comes with the spectrometer at no additional cost, with an intuitive user interface that makes getting started easy, right out of the box. Software development kits (SDKs) that are available in a variety of programming languages increases compatibility with other systems, your existing software stack, and your team’s personal programming preferences, allowing automation of data acquisition and speeding instrument development (see Fig. 4). The ability to develop plug-ins compatible with the existing GUI can simplify data analysis and automate application-specific answers.Really great Raman software should give you the freedom to collect and analyze your data in the way that works best for you. It should offer features essential for Raman, such as control of onboard laser power and detector/measurement parameters, as well as corrections for laser wavelength, spectral response, and thermal drift using known standards. It should also have options for sequential spectra collection and embedded Raman library matching.

Full data transparency: Own your data and analysis

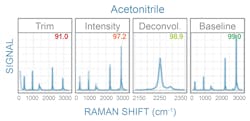

A portable Raman spectrometer should give you full access to your data, in unprocessed form. Many spectrometer manufacturers perform some degree of pre-processing, which, in benchtop spectrometers, may be automatic. Although this is convenient for some applications, it can limit your ability to understand, control, and modify spectral pre-processing and subsequent analysis.

Many researchers and OEMs prefer full data transparency, from access to the raw spectra collected, to control all correction and processing steps thereafter. Having the ability to see, adapt, and customize each step of processing gives you full control over your data, and allows you to create custom spectral processing and analysis algorithms attuned to your specific needs (see Fig. 5). This is particularly important for researchers and OEMs working in fields new to Raman, where novel data processing and analysis methods are an integral part of method development.Choose your Raman provider wisely

Raman spectroscopy has come a long way, and portable systems are sure to take it further—into the field, the clinic, and new industrial settings. The quality of the answers Raman can provide will influenced heavily by the hardware chosen; sensitivity, reliability, and configurability are all pivotal to performance, and should be evaluated carefully. Greater ease of use and data accessibility, meanwhile, can reduce the barriers to the adoption of Raman in a new area.

This makes it important to find a provider who designs and manufactures products specifically for Raman spectroscopy. They should be invested in enabling research, and committed to Raman-based product development that stands above the rest. They’ve put in the time in the lab to understand what a great Raman spectrum looks like, and they get just as excited about Raman as you do. After all, isn’t innovation about enabling next-generation technology in our generation?

Cicely Rathmell | Vice President of Marketing, Wasatch Photonics

Cicely Rathmell, MSc, is vice president of marketing at Wasatch Photonics, and based in Dunedin, FL.