QUANTUM-DOT LASERS: ‘Paint-on’ laser could ease silicon interconnects

Although optical gain in infrared colloidal quantum dots was observed previously, researchers at the University of Toronto (Toronto, ON, Canada) have now developed the first quantum-dot IR laser from solution-processed materials.1 This “paint-on” laser-referring to the ability to apply it as a thin-film layer to solid materials-could conceivably be used to connect microprocessors on a silicon computer chip and enable the monolithic integration of electronic and photonic components.

Because quantum-dot structures can confine electrons and holes in three dimensions (compared to semiconductor lasers, which confine carriers along one axis in quantum wells), the density of states at the band edge is better concentrated and atomic-like states can be spaced much farther apart than the thermal energy kT (k = Boltzmann’s constant, T = temperature). As a result, a quantum-dot laser can produce emission with reduced temperature sensitivity. However, temperature sensitivity is also dependent on quantum-dot diameter: epitaxially grown quantum dots that use III-V semiconductor materials have large diameters compared to the Bohr-excitation diameter, causing temperature sensitivity. In addition, they require a caustic, high-temperature growth process that is highly restrictive for direct growth on silicon.

Small colloids, strong confinement

Conversely, small-radius colloidal quantum dots exhibit very strong quantum confinement-much greater than kT at room temperature. For example, variation in the average diameter of colloidal lead sulfide (PbS) quantum dots from 1 to 10 nm can produce excitonic absorption peaks tunable between 850 and 1800 nm. In addition, these colloidal nanocrystals are solution-processable (the growth is in solution) and compatible with a wide range of substrates, including crystalline silicon.

To build their quantum-dot laser, the researchers first optimized the process conditions that resulted in optical gain for colloidal quantum dots. In the course of their analysis, they learned that maximizing the density of quantum dots per unit volume also maximized the material gain of the system for a given level of population inversion. Rather than using long oleic-acid ligands in solution with the PbS quantum dots (producing a packing fraction of less than 20%), they used short butylamine ligands (to increase the packing fraction to greater than 30%). And, to reduce scattering losses, various solvents were explored to optimize surface smoothness of solid thin films created from solution.

To monitor scattering losses and optimize film thickness, optical waveguides were fabricated from solid thin films of quantum dots, revealing that scattering losses from the nanocrystal-air interface and the nanocrystal oxide substrate were dominant over Rayleigh-scattering losses from the quantum dots.

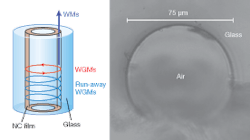

Coated capillary

Finally, to create the laser, a solution containing 5.5 nm diameter PbS colloidal quantum dots was drawn into a 75 µm inner diameter fused-silica microcapillary tube and the solvent was forced to evaporate. The resulting solid thin film on the inner wall of the tube had a thickness of less than 1 µm and thickness uniformity of 10% over a 300 µm length. The capillary was optically pumped with 800 nm, 2 ps pulses at a 1 kHz repetition rate and cooled to a temperature of 80 K. At a pump threshold of 177 µJ/cm2, whispering-gallery-mode lasing oscillation commenced, evidenced by the appearance of a narrow emission peak at 1532 nm.

Although increasing the temperature of the capillary caused the lasing threshold to increase, the wavelength shifted at an average rate of only 0.03 nm/K, 10 times smaller than the spectral shift in quantum-well lasers and twice as low as epitaxial quantum-dot lasers-confirming the low temperature sensitivity of this new colloidal quantum-dot thin-film laser.

“Our aim was to create a laser that emits in the 1.5 µm range, is compatible with standard silicon processing methods, and is easy to process,” says researcher Sjoerd Hoogland. “PbS colloidal nanocrystals do have these properties, with an additional advantage that they potentially can be pumped electrically. Although optical gain had been demonstrated years ago, no lasing operation was obtained. From our optical analysis, we learned that high-quality resonators were needed to provide a sufficient amount of feedback. Therefore we opted for a ring-laser geometry in the form of a microcapillary tube, which did not require additional processing.” Researcher Ted Sargent adds, “We need first to demonstrate room-temperature behavior, and then to show electrically injected lasing, and then we will pursue commercialization.”

REFERENCE

1. S. Hoogland et al., Optics Express 14(8) 3273 (April 17, 2006).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.