UV LASERS: Ytterbium fiber laser is efficiently frequency-quadrupled

To aid in experiments involving optical trapping of ions, researchers at Max-Planck-Institut für Quantenoptik (Garching, Germany) investigated two-step frequency quadrupling of a ytterbium-doped fiber laser. The laser emitted 2 W at its 1118 nm fundamental wavelength; the researchers achieved highly stable narrowband 280 nm radiation that reached the noteworthy power of 275 mW.1

Conversion efficiency and intensity stability for frequency conversion into the UV are of major concern, requiring precise control of phase matching. A fiber laser was chosen by the researchers because such lasers have very high beam quality, making them promising candidates for frequency conversion.

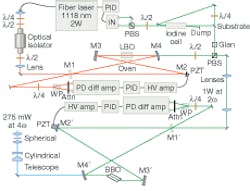

The laser system was based on a commercial diode-pumped ytterbium-fiber oscillator-amplifier laser (see Fig. 1) made by Koheras (Birkerød, Denmark) with a 1118 nm spectral line with a bandwidth of 200 kHz; its 2 W of laser power is combined with an additional 1.2 W of amplified spontaneous emission (ASE) peaking between 1060 and 1100 nm. After the settling of some initial polarization drift upon switching on the laser, polarization was set using one-quarter and one-half optics in the beam.

Two rings

The output was fed via an optical isolator to a first folded-ring resonator that contained a lithium triborate crystal for frequency doubling. Lithium triborate was chosen for its very high optical quality, high damage threshold, and the moderate temperature (89°C) required for noncritical type-I phase matching. The angles of the 18 mm crystal were chosen such that, together with the 10° folding angle of the resonator, a round, nonastigmatic second-harmonic (green) beam was generated. One mirror, which doubled as the output coupler, was shaped as a zero-power lens for the green beam. Approximately 10 mW of the 0.95 W green beam was split off to enable frequency stabilization by locking the laser frequency to an iodine transition, feeding back to a piezoelectric tuner.

The main output of the first ring resonator was fed via two lenses for mode matching to the second one, equipped with a 4 x 4 x 10 mm3 Brewster-cut barium borate crystal in the focus, critically phase matched. The resulting astigmatism was compensated for by a resonator folding angle of 27.4° and an external cylindrical telescope so that a TEM00-shaped output could be obtained. After final beam collimation, 275 mW CW at 280 nm emerged. With respect to 1.8 W of IR radiation coupled into the first ring resonator, the fourth-harmonic efficiency was 15.2%.

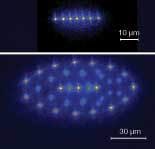

Intensity fluctuations in the UV remained within 2% of the mean value-considerable progress when compared to, for example, the intensity stability of frequency-multiplied dye lasers.For some applications, iodine stabilization may not be necessary. In addition to manipulation of ions for experiments in quantum computing (see Fig. 2) and spectroscopy, applications in holography, metrology, micromachining, and direct writing are possible, as well as use of the 1 W frequency-doubled output for various purposes.

REFERENCE

1. A. Friedenauer et al., Appl. Phys. B: Lasers and Optics, ISSN: 0946-2171 (Paper) 1432 (Online), DOI: 10.1007/s00340-006-2274-2.

About the Author

Uwe Brinkmann

Contributing Editor, Germany

Uwe Brinkmann was Contributing Editor, Germany, for Laser Focus World.