Custom Lasers: Modular Ti:sapphire systems broaden research applications

Once large and complicated, femtosecond Ti:sapphire amplifier systems are now available as compact modular systems that are easy to install, operate, and maintain.

JEFF WOJTKIEWICZ AND ZAZA SARTANIA

Femtosecond Ti:sapphire amplifier systems have become standard research tools in diverse fields such as physics, chemistry, biology, and material science. With the development of compact and reliable femtosecond oscillators, as well as smaller diode-pumped, frequency-doubled Nd:YLF lasers, these ultrafast amplifier systems have also become smaller and easier to use.

Millijoule-level ultrafast laser systems can reach peak intensities on the order of 1016 W/cm2, which for many applications such as micromachining and simple pump-probe experiments is sufficient. However, for some applications, peak intensities from 1017 to 1019 W/cm2 are required to study high-intensity laser-matter interactions, and multistage amplifiers are needed to generate femtosecond pulses at these energy levels (10 to 100 mJ). Traditionally such laser systems were built by the end user or custom designed by a commercial laser manufacturer. With recent advances in laser design and engineering, however, these once complicated lasers have become commercially available in modular systems that are easy to install, operate, and maintain (see Fig. 1).

null

Cryogenic systems

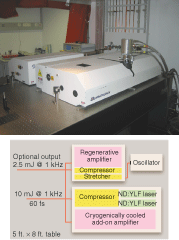

Many fields of research can benefit from lasers operating at kilohertz repetition rates with about 10 mJ pulse energies, which is more than twice the energy currently available from standard systems. Ultrafast pulses, for instance, enable study of molecular dynamics through pump probe experiments. Typically an optical parametric amplifier (OPA) provides pump pulses at different wavelengths. With higher-energy lasers, more energy can be converted to the pump pulse to study larger and more complex molecules and biological systems.

The generation of x-rays through laser-solid interactions is a well-known field of research, which in the past relied upon lasers operating with repetition rates in the tens of hertz. A 10 to 20 mJ kilohertz front end, however, significantly improves signal-to-noise ratios, making such sources attractive for other fields as well, such as research in high-harmonic generation and attosecond pulse studies. All of these research areas require an accessible, stable system with excellent beam quality and low maintenance.

Pump powers above 20 W cause severe thermal lensing, however, and require the Ti:sapphire crystal to be cooled to as low a temperature as possible. Cooling the crystal helps with both heat removal and reducing temperature-induced changes in refractive index (∆n/∆T). Cryogenically cooled lasers have seen many recent advances (see www.laserfocusworld.com/articles/238609). Initially these systems were cooled with liquid-nitrogen Dewar systems that required filling the liquid-nitrogen Dewar multiple times during the day and keeping large amounts of liquid nitrogen on hand to run the system. Currently, closed-loop cryogenic coolers in multipass power amplifiers are easy to maintain and enable output power levels in excess of 20 W without thermal lensing.

Performance improvements in beam quality, stability, and power output of compact, diode-pumped Nd:YLF lasers have also greatly reduced system sizes and maintenance requirements. For example, compact systems (on the order of 4 × 20 in.) can put out 40 W of usable pump light at repetition rates of 10 kHz with diode lifetimes of two years, instead of several months as in lamp-pumped lasers.

We have developed a complete system consisting of a Ti:sapphire oscillator, a kilohertz amplifier, and a cryogenically cooled power amplifier that can deliver 8 mJ of energy with 70-fs pulse durations (see Fig. 2). Such a system can be used with a high-energy OPA and difference frequency generation to produce more than 80 µJ at 10 µm for applications that extend ultrafast science beyond traditional laser physics, such as probing the dynamics of molecular interactions at biointerfaces.

null

Tabletop terawatt systems

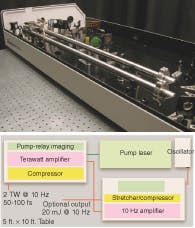

Terawatt laser systems are primarily used for studying high field physics because they can be focused to intensities greater than 1019 W/cm2. At these intensities it is possible to generate x-rays with energies in the 10 to 20 keV range through laser plasma interactions. And the x-rays are generated on the same timescale as the short pulse, providing an ideal source for ultrafast x-ray diffraction studies.

At even higher intensities, the field of the laser pulse is intense enough to immediately strip the electrons from the atoms. As the pulse exits, the electrons rush back to the ions, creating a large plasma wave moving at relativistic speeds. This technique can be used to create electron beams with energies up to 10 MeV, something that traditionally has required a large facility such as a linear accelerator.

When the beam propagates through the atmosphere, its high intensity causes it to self-focus, which reduces the beam size to a point at which ionization occurs. This in turn defocuses the beam and the combination of the two effects (a process known as filamentation) enables the beam to propagate for hundreds of meters. Because the ionization causes white-light generation, the filaments are extremely useful for multispectral, atmospheric lidar. The resulting plasma channels are also conductive and can be used to trigger lightning for research purposes, as well as for protection applications. Electrically conductive filaments could be used to guide lightning away from a space shuttle sitting on the launch pad, for instance, and toward a lightning rod.

Terawatt systems have unique design and engineering requirements, however. They require high dispersion stretcher/compressor pairs to achieve safe peak power levels during amplification. In addition, the laser amplifiers typically use a standard bowtie multipass design, and the saturation fluence of 1 J/cm2 for Ti:sapphire determines the size of the beam in the crystal. The pump laser for these amplifiers is a frequency-doubled, flashlamp-pumped, Nd:YAG laser with pulse energies of 1000 mJ. However, the beams from these lasers are highly multimode. As the beam propagates, “hot spots” develop, reducing the beam quality of the amplified IR pulse. It is standard for these systems to use vacuum relay imaging to maintain good beam quality on the crystal.

Systems above the 2-TW level must use an external vacuum compressor because the peak power exceeds the point at which nonlinear effects start to appear in air. Typically, these systems require elaborate experiments that also must be conducted in a vacuum, however, eliminating the need for an additional vacuum compressor.

Modular turnkey terawatt systems such as these are convenient to install and maintain. We have developed a system that fits easily on a 5 × 10 ft optical table, making it ideal for a wide variety of research areas that require ultrashort, high-intensity pulses (see Fig. 3).

null

JEFF WOJTKIEWICZ is a senior laser scientist and ZAZA SARTANIA is executive vice president of the scientific division at Quantronix, 41 Research Way, East Setauket, NY 11733; e-mail: [email protected]; www.quantronixlasers.com.