Cholesteric LCDs show images after power is turned off

Paper has always been a remarkable display technology. Its contrast, resolution, price, portability, passivity—no power consumption once the image is drawn—and wide viewing angle are admirable. Its major disadvantages are an effectively nonexistent redraw rate and an inability to be addressed electronically. A flat-panel display technology that could match the advantages of paper and offer electronic control and redraw could allow the "electronic books" of science fiction—media that combine the data-processing abilities of computers with the user-interface of a book or newspaper.

Cholesteric liquid-crystal displays (LCDs), while not having all the advantages of paper, may be closing the technology gap. They have characteristics that make them desirable for specific applications requiring low-power operation, wide viewing angles, and brightness in daylight (see photo at top of this page).

Cholesteric bistable LCDs are one of several bistable liquid-crystal technologies (two others are ferroelectric and bistable-twist liquid crystals). Bistable devices have two stable states that can be maintained without power—thus reducing the amount of power required by the display. These devices also can use a simple passive-matrix addressing design rather than the more-expensive active-matrix designs.

Cholesteric LCDs currently being commercialized by Kent Displays Inc. (Kent, OH) offer some advantages over existing conventional liquid-crystal displays, and new developments may offer more advantages in the future. The technology could, for example, be used to make inexpensive lightweight, full-color video-rate displays that consume power only when the display is being redrawn.

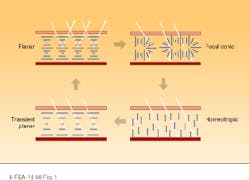

Cholesteric liquid crystals change their texture, thus their optical properties, as voltage is applied and withdrawn (see Fig. 1). In the absence of power, the material remains in one of two states—planar (reflective) or focal conic (transparent)—and this provides bistability that twisted-nematic liquid crystals lack (see Laser Focus World, Nov. 1997, p. 137). When the material is in planar texture (that is, a planar state), the chiral molecules act as Bragg reflectors for light at a wavelength comparable to the pitch of the liquid crystals and with circular polarization in the same direction as the helical twist. Because the pitch can be determined during manufacture, this reflective color of the cell can be well controlled.A low-voltage pulse switches the reflective planar texture to a focal conic texture by twisting the liquid-crystal helix, which makes the crystal transparent to the back surface of the cell. A higher-voltage pulse is sufficient to untwist the helix, driving the display back to the reflective planar state upon removal of the pulse. Contrast can be enhanced by carefully choosing the color reflected by the liquid crystal and the color of the substrate.

Small domains

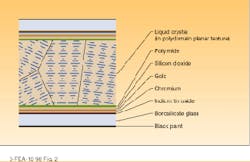

Researchers at Kent State University Liquid Crystal Institute (Kent, OH) discovered two ways of breaking the planar texture into micron-sized domains. Small amounts of liquid crystal could either be distributed through a polymer network or the surface of the cell could be treated to provide the same fractured domains (see Fig. 2).With small domains, the orientation of the planar structure is distributed, which, in turn, distributes the reflected light over a broad range of angles, much like light reflected from a mosaic of small mirrors slightly tilted in differing directions. The fine-grained domain structure increases the viewing angle for these displays well beyond the usual for liquid-crystal displays, as well as giving added stability to the focal conic state. The small domains also allow for gray scale in the display because an appropriate electrical pulse can adjust the relative densities of the domains in the reflective planar texture.

Brighter with less power

Unlike typical LCDs, the cholesteric bistable liquid crystals do not require polarizers. The most obvious benefit of this is that cholesteric displays reflect almost 40% of the incoming light. By comparison, paper reflects about 80%, and twisted-nematic LCDs reflect about 15%. The increased reflectivity is also responsible for the increased contrast between pixels in the planar and focal conic states—about 25:1 from directly in front of the display, although it drops off to about 11:1 at large viewing angles. A corollary benefit is that, in many cases, display backlighting can be eliminated.

Thus cholesteric displays save energy in two ways—by not requiring power when the display is static and by not requiring an integrated light source. Both are important benefits for portable electronics such as personal digital assistants, cell phones, calculators, pagers, global-positioning-system receivers, and portable data-collection devices that include displays.

The lack of polarizers opens up another possibility—lightweight displays with substrates of plastic, rather than glass. Plastic is not an option for regular polarized LCDs because it is birefringent. Plastic could be used for cholesteric LCDs, however, which would be an advantage for hand-held devices. Last year, researchers at Kent Displays reported a 6-in.-diagonal 1/2 VGA display with a resolution of about 133 dots per inch (dpi). Rainer Bunz and other researchers at the University of Stuttgart (Germany) have also developed prototypes of a 6-in.-diagonal VGA display with a resolution of about 133 dpi.

Passive addressing, dynamic drive

Active-matrix technologies, in which each pixel has a transistor, allow fast addressing but also increase the complexity, cost, and power requirements of LCDs. Bistability can reduce the complexity of the drive scheme. Passive addressing, in which individual pixels are identified by row and column one line at a time, can address a line of pixels in 5 ms. An advantage of this addressing method is that an increase in resolution of the display does not require a trade-off with contrast. Researchers at the Liquid Crystal Institute and the University of Stuttgart have developed a passively addressed 14-in.-diagonal display with 200-dpi resolution—in other words, with 3.8 Mpixels.

A dynamic-drive scheme developed by Kent Displays increases the addressing speed dramatically while lowering the voltages needed and allowing the use of existing 45-V driver chips designed for super-twisted-nematic LCDs. According to J. William Doane, Chief Science Officer at Kent Displays and previously director of the Liquid Crystal Institute, a typical display, with a cell-wall spacing of 4.5 µm, could use one of these drive chips to switch crystal texture from planar to focal conic using a 10-V pulse, from planar to gray scale using a pulse between 7 and 10 V, and from focal conic back to planar using a 35-V pulse.

Here and to come

Kent Displays has several products commercially available. Two displays are designed for large signs, such as at airports or kiosks—the Infosign, with a 12 × 1.5-in. viewing area and 20-dpi resolution, and the QUAD module, which displays four characters, each measuring 4.5 × 3.0 in. with a character resolution of 3 dpi.

The company also offers a 1/8 VGA display (240 × 160 matrix) with 100-dpi resolution in an active viewing area of 1.6 × 2.4 in. (40.6 × 61 mm). This display is designed for mobile electronics and is available in both 5- and 3-V models.

The commercial displays, designed for OEM use, are available in several color combinations, but both black-on-white and full-color displays are being developed. At the 1997 Society for Information Display conference (SID; Boston, MA), R. Q. Ma and D.-K. Yang of Kent State University demonstrated a white-and-black display. The re searchers invented a polymer-stabilized display in which a small amount of polymer network dispersed in the liquid crystal broadened the reflection spectrum of the planar texture. They demonstrated a four-pixel array with contrast and viewing angle comparable to that of a newspaper.

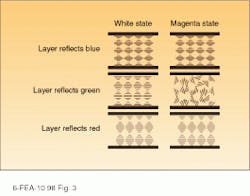

Full-color displays are being developed now. A full-color display with 4096 colors was demonstrated at SID ‘98 in Anaheim, CA. Instead of clustering three pixels—one each reflecting red, green, and blue—side by side, the technology allows stacking of cells, such that incident light first passes through a blue reflecting layer, then a green, then a red layer. If, for example, the green-reflecting layer was switched to the focal-conic texture, then the reflected light from the display would appear magenta (see Fig. 3). Gray levels for each cell introduce intermediate color shades. Advantages of this approach are that it provides color without decreasing display resolution and the multiple layers increase the reflectivity, thus making the reflective display brighter. Challenges lay in keeping the layers thin enough to avoid parallax problems.This display technology shows promise of being manufacturable on polymer substrates, with RGB color, and with dynamic drives. If cholesteric LCDs can be developed with these characteristics, they may provide lightweight, full-color, video-rate flat-panel displays that do not draw power unless the display is being redrawn. Although mobile devices are the first obvious applications, such devices may also be cost-effective in standard displays.