INTEGRATED PHOTONICS: Slow light is created on a printed-circuit board

The generation of “slow light” (in which the group velocity of light in a material is slowed down substantially due to a specially tailored dispersion profile) is potentially valuable for use in optical circuits intended for telecommunications or optical data processing. Slow-light generation was first accomplished using electromagnetically induced transparency, which normally requires a complex and delicate lab setup, and more recently has been achieved using stimulated Brillouin and Raman scattering (SBS and SRS) in optical fiber and integrated photonic chips.

Now, a group of Russian and American scientists has produced slow light in polymer waveguides on an ordinary printed-circuit board (PCB), widening the potential use of this effect.1 In the setup, SBS is used to produce a widely tunable optical delay useful for many purposes.

SBS-induced slow light

The researchers, from M.V. Lomonosov Moscow State University and the Russian Academy of Sciences (both of Moscow, Russia) and Texas A&M University (College Station, TX), created arrays of identical 5-cm-long, 50 × 50 µm waveguides on a PCB using UV lithography. The waveguides have a core refractive index of 1.46 at 800 nm and a cladding index of 1.40 at 800 nm, with a Raman gain spectrum dominated by a carbon-hydrogen vibrational mode with a wavenumber of about 3000 cm-1, corresponding to a vibrational period of 11 fs.

Stokes pulses are produced by a Ti:sapphire laser system containing a modelocked maser oscillator emitting 40 fs pulses and a multipass amplifier emitting 60 fs pulses with an 800 nm center wavelength and a typical bandwidth of 5 nm. Pump pulses with a 100 fs duration and a 650 nm center wavelength are produced by a frequency-tunable optical parametric oscillator. As in other SBS-induced slow-light setups, the pump pulses amplify the Stokes pulses and also induce a change in the refractive index of the waveguide, slowing down the Stokes pulses. The Stokes pulses were varied in duration between 60 and 500 fs for the experiment.

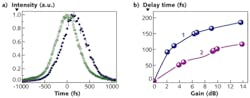

The sum-frequency signal produced by the Stokes output along with 200 fs, 800 nm reference pulses in a beta barium borate crystal was created and measured as a function of the delay time between the Stokes and reference pulses.

The researchers used a spatial filter to make sure that the bandwidth of the Stokes pulses stayed under the Raman linewidth of 5 nm, thus creating the best conditions for the coupling between the pump and Stokes pulses. Because the waveguides were multimode, the output Stokes pulses were unavoidably stretched in duration by up to 10%.

A straightforward theoretical approach predicts a time delay that is linear in proportion to the gain, but the experimental results show some saturation for high gain as a result of Kerr optical nonlinearity in the polymer (see figure). Optical group delays up to 200 fs were produced with the optimum 5 nm Stokes bandwidth and a 14 dB gain.

The researchers note that the interaction length for the pump and Stokes pulses in the polymer waveguide is limited by the mismatch in group index between the two types of pulses (for example, the interaction length for the Stokes pulses with 5 nm bandwidth is about 13 mm). There are several approaches to creating a longer interaction length, say the researchers. These include mixing of spatial or polarization modes, the use of a multilayer cladding, or a better designed waveguide-dispersion profile.

For example, a rectangular polymer waveguide 0.9 × 1.5 µm in size has a modeled 9 cm interaction length for orthogonally polarized pump and Stokes pulses, producing up to 1.4 ps delays for 100 fs pulses.

In addition, different polymers with a higher density of carbon-hydrogen bonds should boost the gain; the group has already determined in preliminary experiments with thin polymer films that the gain could be increased by a factor of 4 to 5.

REFERENCE

1. A.A. Lanin et al., Opt. Lett., 36, 10, 1788 (May 15, 2011).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.