Quantum-dot laser operates at startlingly high temperatures

A quantum-dot (QD) laser created by a team of Japanese researchers is capable of continuous-wave output at temperatures up to 220ºC, making it usable in extreme environments such as those encountered deep underground in oil and gas drilling. Gain at such high temperatures was achieved by suppressing indium out-diffusion as the indium arsenide QDs were being fabricated by molecular-beam epitaxy. The resulting eight-layer structure had a high density of 5.9 × 1010 QDs per square centimeter per layer. In addition, because the ground state and first excited state were separated by a large amount (80 mV), higher-order lasing at very high temperatures was suppressed. The team was made up of scientists from QD Laser and Fujitsu Laboratories (both in Kanagawa) and from the University of Tokyo.

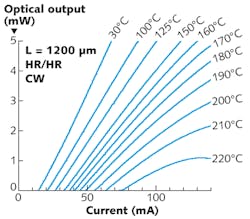

The laser consists of n and p aluminum gallium arsenide (AlGaAs) cladding layers and partially p-doped GaAs barriers. It emits at a wavelength of 1268 nm at 30ºC, which changes approximately linearly as a function of temperature to a wavelength of 1359 nm at 220ºC (all wavelengths fall well within the low-loss window of fused silica optics). Optical output is 2 mW at 210ºC and 1 mW at 220ºC; threshold currents are 15, 27, and 55 mA at 30ºC, 125ºC, and 200ºC.

Contact Yasuhiko Arakawa at [email protected].

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.