The quest for inexpensive wavelength-division-multiplexing (WDM) devices for use in campus and access networks has led numerous research groups to the use of polymer, mainly in the form of arrayed-waveguide-grating (AWG) planar devices. An AWG contains many curved waveguides of incrementally varying length that function as a grating and give wavelength dependence to the output, allowing WDM. But because the bend radii of the curves must be large to avoid waveguiding losses, the devices themselves are large and can be costly.

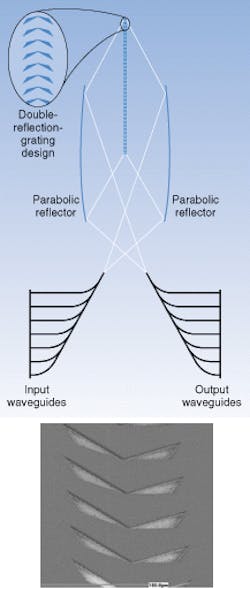

Researchers at the University of Bristol (Bristol, England) have developed an alternative solution that promises small, easy-to-make WDM devices. While maintaining the planar waveguide, the Bristol approach scraps the AWG in favor of slab waveguide propagation and quasi-free-space integrated optical elements that include a double-reflective grating (DRG; top of figure). The slab waveguide consists of a silicon substrate, cladding layers of poly(methylmethacrylate), and a core layer of poly(methylglutarimide). Device elements are produced photolithographically using a single mask step and deep reactive-ion etch, resulting in features etched through the core (bottom).

Input fiber-coupled waveguides bring in signals at different wavelengths, all of which are launched into planar space and collimated by a parabolic reflector. The beam passes through the DRG and is focused by a second parabolic reflector so that it enters an output waveguide. The four-channel prototype contains mirror-image input and output waveguide arrays for experimentation.

The 28.5-µm-pitch DRG at the heart of the device solves two problems that exist in a standard transmission grating. When passed through a standard grating with single-reflective elements, a collimated beam with nonuniform intensity distribution gets chopped up and, due to image reversal, is reassembled imperfectly, shifting power into unwanted sidelobes. A DRG, however, reassembles the beam to its original intensity distribution. In addition, the geometry of a DRG allows the individual elements to have nonilluminated extensions that reduce the effects of imperfect corner construction.

The prototype operates at 1538 nm, with a channel spacing of 1.6 nm and passband widths at -3 and -20 dB at 0.9 and 1.5 nm, respectively, giving a 3/20-dB passband width ratio of 48%. Coupling between input waveguides in the prototype and flaws in the grating elements raised the crosstalk floor to ±15 dB.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.