JAPANWATCH: ULTRAFAST LASERS: Plasma optical waveguide provides new pathway

Incorporating news from O plus E magazine, Tokyo

TAKASHIThe Japan Atomic Energy Research Institute has developed a stable plasma optical waveguide that can transport ultrahigh-power, ultrashort-pulse laser light, condensed to a pulsewidth of 40 µm, over a distance of 20 mm. This result advances the development of compact high-functionality particle accelerators and x-ray lasers.

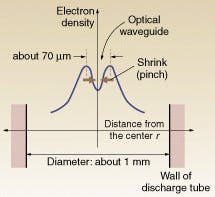

A plasma optical waveguide is an optical waveguide based on the refractive-index distribution arising from the electron density distribution of the plasma. In this experiment, helium gas was put in a cylindrical discharge tube 1 mm in diameter by 20 mm long. Discharge is induced by applying electricity to the electrodes on the ends of the tube. Ionization of the gas begins at the cylinder wall, but the diameter of ionized gas quickly shrinks and reaches a waveguide state (see figure). This effect results from charged electrons coming under the influence of a Lorentz force from the magentic field generated by the current. The electrons are then pushed toward the central axis in a "pinch phenomenon."

PHOTO. Plasma optical waveguide uses refractive index distribution arising from the electron density distribution of the plasma. Specifically, a plasma with an electron-density distribution that is rotationally symmetrical about the vertical axis results in a low-electron-density region with a high refractive index, which functions as a waveguide.

Until now, this method could not be used to make a stable waveguide because of increasing instability in the plasma. However, by executing a "preliminary" ionization so that the initial condition of the plasma is uniform and by adjusting the applied current more quickly than instability increases, a uniform and stable optical waveguide can be maintained for approximately 1 ns. This time is sufficient for guiding ultrashort optical pulses.

Because of this development, compact, high-functionality accelerators can be created for charged particles such as electrons. Laser acceleration of electrons has been investigated in the past. If ultrahigh-power pulsed laser light is collected inside plasma, plasma waves result. By injecting electrons so that they match the timing of the electric field gradient caused by the plasma waves, the electrons can be accelerated. However, with this method, only electrons near the point where the light is condensed can be accelerated. With this plasma optical waveguide, particles can continue to accelerate along its length. High-frequency acceleration tubes have had to be several hundred meters long; this waveguide may reduce that length to only a few centimeters.

The electron distribution required for specific tasks varies, but this technology allows the distribution to be controlled by changing the discharge parameters inside the electron tube. Using these results, the research group is pursuing research in electron accelerators and x-ray lasers.

Courtesy of O plus E magazine, Tokyo

CORRECTION

In the October Japanwatch story "Homogeneous superfine silicon particles light up" (p. 48), the name of one research institute was incorrectly given as the Mechanical Research Laboratory. The accurate English translation should read Mechanical Engineering Laboratory, AIST-MITI.