Recent experiments with an unusual technology known as nanotubes reveals that they can be efficient emitters of electrons. When fabricated into flat sheets of addressable pixels, nanotubes could conceivably be part of field-emission displays (FEDs), a class of flat-panel displays that use an array of electron emitters to strike a phosphor-coated screen, producing an image that is similar to those on CRTs. However, several years of development work are anticipated before nanotubes can be proved viable for manufacturing FED displays.

In one approach for making FED emitters, thousands of tiny microtip cones, each about 1 ?m in diameter, are fabricated for each pixel of the display. Alternatively, some researchers are using diamond-like films that contain nanoscale crystalline structures. While the material is important for electron emission, so too is the structure. It appears that the sharper the tip and thinner the geometry, the better the structure is at producing large electric fields, which are conducive to more-efficient electron emission.

Nanotubes are all-carbon, nanometer-scale, hollow filaments that were first discovered in 1991 by Sumio Iijima at NEC (Tokyo, Japan) and reported in Nature, Nov. 7, 1991. Most research work involving the material has concentrated upon their potential use as micro-carriers of drugs or as nanowires. Recently, physicists at Ecole Polytechnique Federale de Lausanne (Lausanne, Switzerland) and the Laboratorio Nacional de Luz Sincrotron (Campinas, Brazil), fashioned the material into an electron-emitting configuration suitable for displays.

Nanotubes are much smaller than microtips, perhaps 5 to 15 nm in diameter, and more uniform in their size than irregularly shaped diamond-like nano-crystalline materials. This property indicates they should be very good electron emitters. But to use them in a practical device, developers must prove that the nanotubes can be assembled into uniform arrays with all of the tubes arranged perpendicular to the surface.

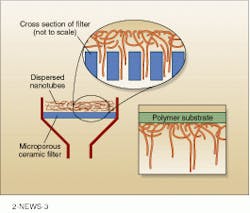

Swiss researchers Walt de Heer and Andre Charelain were able to do this last year, successfully demonstrating the fabrication of hundreds of thousands of vertically oriented nanotubes. First they passed a solution of nanotubes through an extremely fine-pored ceramic filter. Nanotubes of the right size lodged in the holes of the filter, while the remaining nanotubes lay in a tangled mess on top of them, forming a film. A polymer substrate was pressed against this film, bonding to the disordered nanotubes. As the substrate was separated from the filter, the vertically oriented nanotubes were exposed (see figure). Such processes have cost advantages over the photolithographic techniques required to fabricate microtips.

Last fall, the researchers added a conductive grid to the structure, biased the array, and detected electron emission. These results indicate that the electron magnification factor of the devices is about 100 times higher than those obtained with conventional FED cone emitters, confirming the efficiency of electron emission. In addition, de Heer?s group noted no degradation of the devices, when operated for days at less than 1000 V.

Andrew Rinzler, a physicist at Rice University (Houston, TX), and his colleagues are also doing research on nanotubes. They recently measured the output current from a single nanotube at around 1 A for a 75-V bias. By comparison, larger microtips need about 200 V to achieve the same current. OThe performance of nanotubes as electron emitters is very exciting and has the potential to be a lower-cost alternative to other FED fabrication technologies," said Rinzler. "I don?t think much more fundamental research is needed, but rather, engineering development to find out how to use nanotubes in real displays."

One area of concern is achieving the uniformity and density of nanotubes needed for high-resolution displays. Even though filters with grids down to 20 nm are now possible, some holes could contain many nanotubes, while adjacent holes might contain none. "A 10-in. VGA display has large pixel areas, so that should be no problem," continued Rinzler. "What is not clear is how well nanotubes will work with much-smaller pixel sizes. Statistically, you need a lot of nanotubes per pixel to even out variations in brightness."

It now appears that FEDs are going to have to achieve very high resolutions or very bright outputs if they are to compete commercially. Emerging FED developers such as Pixtech (Mountain View, CA) already concede that they may not be able to compete in the lucrative laptop market, because the Japanese have made outstanding progress in improving performance and reducing power consumption and weight of their liquid-crystal flat-panel displays. However, it is likely to be three to five years before nanotubes show up in FEDs, and whether these devices make it in the commercial market remains to be seen.

Chris Chinnock

Chris Chinnock is president and owner of Insight Media in Norwalk, CT. He is a 30-year display industry veteran with experiences in displays, broadcast, cinema, ProAV, and consumer electronics.