Laser Raman scattering cools GaN

While laser-based optical refrigeration methods are typically based on anti-Stokes fluorescence, researchers at Lehigh University (Bethlehem, PA) and Johns Hopkins University (Baltimore, MD) may soon succeed in cooling gallium nitride (GaN)—which has one of the highest longitudinal optical (LO) phonon energies of any semiconductor material at 91.8 meV—using anti-Stokes Raman scattering.

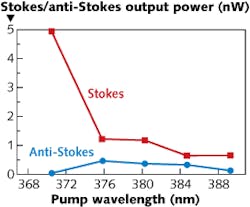

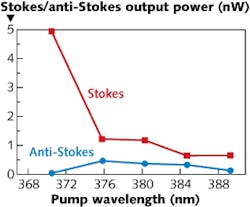

A frequency-doubled Ti:sapphire laser (tunable from 370–389 nm) illuminates an undoped, 1-µm-thick GaN film. Anti-Stokes and Stokes signals are collected by a spectrometer and detected by a photomultiplier tube. The laser radiation is then optimized to have an LO phonon energy lower than that of the bandgap of GaN, maximizing the anti-Stokes Raman intensity while eliminating the emission of hot LO phonons through photogenerated carriers that could cause GaN heating. It turns out that the spectral dependence of Stokes and anti-Stokes Raman signals is quite different. As pump wavelength is varied, laser cooling occurs if the anti-Stokes Raman intensity is enhanced by a factor of 2.0, making it equal to the Stokes signal and reaching the threshold for GaN cooling. To meet this Stokes/anti-Stokes signal equality requirement, the researchers plan to use an optical resonator only resonating at the wavelength of the anti-Stokes signal to enhance the signal by a factor of 2.0. Contact Yujie Ding at[email protected].