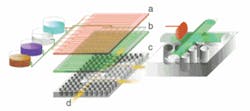

Optical systems are not as flexible as electronic systems, which can be arbitrarily reprogrammed to perform different tasks, but researchers at the California Institute of Technology (Caltech; Pasadena, CA), Harvard University (Cambridge, MA), and the University of California-San Diego hope to remedy this by taking advantage of recent advances at their institutions in microfluidics, soft lithography, and nanophotonics. By fusing these three technologies, they hope to develop “optofluidic” components using nanometer-sized fluidic pathways to mix and pump liquids into and out of the optical path (see figure).

In a proposed optofluidic system composed of: a microfluidic valve network (a), microfluidic channels (b), a photonic-bandgap structure (c), and optical beams (d), an optical substrate is integrated with a microfluidic structure that performs functions such as reconfiguration of functions, adaptation of properties, distribution of chemicals to be analyzed, and temperature stabilization.

The introduction of liquids into an optical structure enables flexible fine-tuning and even reconfiguration of optical circuits in response to changing environments, according to Dmitri Psaltis, founding director of a new Center for Optofluidic Integration at Caltech, launched earlier this year with a four-year, $8 million basic-research grant from the Defense Advanced Research Projects Agency (DARPA; Arlington, VA).

“The basic idea of the center is to build optical devices for imaging, fiberoptics, communications, and other applications, and to transcend the limitations of optical devices made out of traditional materials like glass,” Psaltis said. “A glass lens, for example, is relatively unchangeable optically. Our idea is to use fluidics as a means of modifying optics.”

Data storage

Among the various application foci within the center, data storage is key for the Psaltis research group. Instead of laser-writing pits into a DVD or CD substrate, they are developing microfluid chambers on a similar substrate to provide a photoluminescent multiwavelength data-storage system, according to Jim Adleman, a member of the Psaltis group. They write certain combinations of fluorescent markers into these chambers, which yield different emission lines and allow them to store multiple bits in a single DVD or CD pit.

The microfluidics can be synthesized on the chip and provide a persistent memory (as opposed to a RAM). And with “n” different species of markers, there are 2n possible states for each pit, yielding an exponential improvement over electronic storage capacity. In addition, different intensity levels correspond to different concentrations, adding more variability. Such a system is expected to provide more environmental robustness than electronics, a key feature for DARPA’s battlefield applications, because the physical material is stored in reservoirs and is not susceptible to erasure as with electronic memories.

In a separate project, Changhuei Yang is working with Psaltis on microfluidic-based imaging devices to provide resolution down to tens of nanometers. A proposed application is a high-throughput method of profiling the shapes of cells, bacteria, and viruses that might eventually serve as a high-resolution alternative to flow cytometry.

Stephen Quake’s group at Caltech is working on high-density microfluidic devices with an aim similar to that of the semiconductor industry-to increase packing density. They are currently working toward 100,000 microfluidic valves within a 1-cm2 surface area, with potential applications such as lab-on-a-chip experiments using optical spectroscopy to interrogate chemical reactions.

Optofluidic lasers

Based on the quantum-cascade (QC) lasers that he invented at Bell Labs in 1994, Federico Capasso and his colleagues are working at Harvard to create optofluidic-laser platforms. The QC-laser spectrum covers the mid- to far-IR from 3.5 to 100‑µm in which device wavelength is tailored by changing the layer thickness.

The use of fluidics makes possible a new QC laser type with holes drilled or etched near or in the active regions and fluids micropumped through the holes, Capasso said. Initial experiments will evaluate the capacity for making lasers reconfigurable by pumping through fluids with different refractive indices, and also by including different biochemical materials in the fluids to perhaps make new types of on-chip chemical detectors. Axel Scherer at Caltech is also drilling holes in semiconductor lasers for microfluidics, but he is working with diode as opposed to QC lasers, Capasso said.

Fluid fiberoptics

Replacing solid optical fibers with fluid waveguides is the focus of George Whiteside’s group at Harvard, according to team member Dmitri Vezenov. They have shown that with a very small channel they can take advantage of flow characteristics in which two fluids flowing side by side do not mix. The fluids form an optically smooth interface and the characteristics can be changed dynamically by changing characteristics such as fluid direction, the fluids themselves (indices of refraction), and by adding solvents such as fluorescent dyes.

The laminar fluid flow in these 10- to 100-µm-wide channels is due to a balance of viscous and inertial forces that Vezenov likened to the forces that maintain the stripes in striped toothpaste. Potential applications include bioanalysis (lab on a chip) and eventual telecommunication applications (for instance, providing a means to switch between multi- and single-mode fiber by adjusting fluid flow). Ultimately, the addition of fluorescent molecules to liquid in a waveguide core may enable light generation-lasing on a chip.