Optical center to continue despite loss of funding

In September, the fifth annual affiliates meeting of the Center for Nonlinear Optical Materials (CNOM) at Stanford University (Palo Alto, CA) provided an opportunity for looking both forward and backward in terms of the center`s achievements and the continued existence of the center itself. Federal funding for CNOM will run out in January.

Faculty at the center have decided to continue its industry affiliates program, however, while seeking new sources of federal funding. On the first day of the two-day meeting, CNOM director Robert Byer announced that the 1998 affiliates meeting will be held regardless of the federal funding situation.

CNOM was founded in 1992 under a federal university research initiative (URI) program that provided for three years of funding and a two-year renewal option. The full five years was completed on August 1, and CNOM is currently operating on a six-month, no-cost extension, Byer said.

"We`ve been actively seeking other sponsors so that we could recompete for [funding]," Byer said. "[The center] has provided real value in the commercial area and to government sponsors." Possible sources of federal sponsorship include the National Science Foundation and various agencies in the Department of Defense, he said.

The purpose of CNOM "is to discover and to improve nonlinear optical materials and to transfer the knowledge gained to the commercial sector," says the CNOM annual report for the 12-month period ending in August 1997. Notable successes during the five-year period include electric-field poling of lithium niobate and lithium tantalate, as well as use of periodically poled ferroelectric crystals in quasi-phase-matched (QPM) nonlinear interactions. These successes were evidenced at CLEO `97 (Baltimore, MD) by QPM optical parametric oscillator demonstrations put on by three companies.

To date, the lion`s share of CNOM funding—$1.9 million a year—has come from the URI program, and sponsorship from corporate affiliates (currently including 21 laser, materials, instrument, and aerospace companies from the USA, Asia, and Europe) has increased that annual amount by another 10%, Byer said. He is hoping that the affiliates will also help in taking the center`s case to the government. "We believe the presence here [at the CNOM affiliates meeting] of [almost] 150 scientists and engineers demonstrates that there is a real interest in this technical area," he said.

The focus of technical interest at the 1997 meeting evidenced an interweaving of scientific and commercial themes. Manufacturing capabilities reported at the 1996 meeting are capable, in large volumes, of reducing the manufacturing cost from about $1000 for a typically cut, polished, and coated nonlinear crystal to about $1 per chip on a commercially produced wafer, Byer said.

Scientific presentations throughout the 1997 meeting explored potential commercial applications of PPLN, and an industry workshop focused on the need for high-volume markets to make the emerging manufacturing capabilities pay off.

Quasi-phase-matching

From the scientific side a major focus was on the use of quasi-phase-matching interactions in nonlinear materials for frequency conversion and pulse shaping of ultrafast lasers. "Femtosecond laser technology opens a whole new avenue," Byer said. "So that`s an interesting area where you are seeing commercial products also being developed."

David Hanna, deputy director of the Optoelectronics Research Centre (ORC) at the University of Southampton (Southampton, England), who gave an invited plenary talk on progress in QPM nonlinear devices, emphasized the use of PPLN with modelocked, femtosecond-pulse sources to achieve high gain while operating at low-threshold power levels.

"The high gain allows tuning of the idler wave well into the infrared absorption edge and has also resulted in significant pulse compression by more than an order of magnitude relative to pump pulse duration," Hanna said. "The low-threshold operation promises future possibilities of pumping directly with diode lasers, or with fiber lasers, for which there would appear to be a particularly good synergy."

Hanna also reviewed research being done at ORC, where fiber laser work by Hanna and colleagues (see Laser Focus World, Sept. 1997, p. 87), as well as industry-related research with fiber Bragg gratings, was recognized in September with total awards of more than 𧶀,000 ($300,000) from the Realizing Our Potential Award program in the United Kingdom.

Several presentations during the CNOM meeting also discussed a collaboration between researchers at Stanford and IMRA America (Ann Arbor, MI) in using PPLN technology to develop a new class of nonlinear ultrafast devices for use in fiberoptic laser systems.

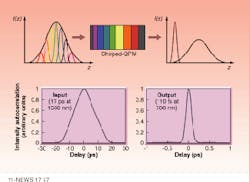

In one of these presentations, Mark Arbore, a PhD student in Electrical Engineering at Stanford working under the supervision of CNOM associate director Martin Fejer, described a method for compressing optical pulses during second-harmonic generation. Using QPM PPLN, the researchers compressed chirped 17-ps pulses at 1560 nm into transform-limited 110-fs pulses at 780 nm and demonstrated up to 40% average conversion efficiency for generation of femtosecond pulses at 780 nm with an average power in excess of 70 mW (see figure).

A primary focus of the CNOM charter when it was originally funded five years ago had to do with technology for information storage and display that would be needed for high-definition color displays. Richard Wallenstein, an invited speaker from Kaiserslautern University (Kaiserslautern, Germany) discussed the application of this technology to projection displays, such as the September demonstration at the Internationale Funkaustellung consumer electronics show in Berlin (see related story on p. 52). Wallenstein`s group used bulk crystals to achieve 6-W output in each of the three primary colors using harmonic and parametric conversion of a modelocked 1-µm laser.

Taking an approach different from Wallenstein, CNOM researchers poled lithium niobate to periods of 6 µm for first-order frequency doubling of Nd:YAG (See Laser Focus World, May 1997, p. 105). Using continuous-wave, single-pass second-harmonic generation, 2.7 W of 532-nm output was produced from 6 W of 1064-nm input, Robert Byer said. Subsequently, using a 532-nm pumped optical parametric oscillator, the researchers plan to generate red and blue frequencies for RGB laser displays.

In addition to quasi-phase-matching and ultrafast nonlinear effects, scientific presentations at the CNOM meeting also covered holographic data storage and both thin-film and bulk material and devices.

An example of rapid product development that caught most attendees by surprise was the news that Fuji film is already selling digital photoprinting systems that depend on blue and green laser light generated by frequency conversion using periodically poled crystals of lithium niobate doped with magnesium oxide.

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.