Visible sources venture beyond research markets

Bruce Craig

Diode-pumped lasers are the fastest-growing segment of the worldwide nondiode-laser market. The most recent Laser Focus World survey projects sales of nearly $90 million in 1997—representing an annual growth rate of more than 60%—and this estimate is considered to be conservative (see Laser Focus World, Jan. 1997, p. 72).

In fact, the market appears to be well positioned to take advantage of innovative products for both research and development and industrial applications--R&D funding is rebounding from the low levels of the early 1990s and industrial activity is reaching new heights. Market penetration of diode-pumped solid-state lasers has been limited, however, with the major successes being in research and in some material-processing applications. There are currently no solid-state solutions for applications that require a moderate- to high-power continuous-wave (CW) ultraviolet (UV) laser source, for example. Nonetheless, high-power (more than 1 W) diode-pumped visible-output lasers have gained a stronghold in a market that, until recently, was dominated by water-cooled ion lasers. Several industrial applications have benefited from this technology shift.

Green-emitting lasers

Within the last two years, there has been tremendous activity involving high-power green diode-pumped CW lasers. Product offerings include a 2-W-output system from Lightwave Electronics (Mountain View, CA), the Millennia from Spectra-Physics Lasers (Mountain View, CA)—with 2-, 5-, and 10-W options (see photo), the Verdi from Coherent (Santa Clara, CA)—in 2- and 5-W options, and a 1-W system from Edinburgh Instruments (Edinburgh, Scotland). All of these units use high-power (usually 20 W) diode-laser bars as the pump source. For practical reasons, the output from the bars is usually fiber-coupled to a compact laser head containing a neodymium-doped gain medium--typically Nd:YVO4 because of its high-gain cross section.

The green output is generated by intracavity frequency doubling in a lithium triborate (LBO) or a potassium titanyl phosphate (KTP) crystal. To achieve low-noise second-harmonic output two approaches are used. In one, embodied in the Verdi, the laser is forced to oscillate on a single longitudinal mode; in the other approach, used in the Millennia, oscillation is allowed over about 100 longitudinal modes.1,2 Each of these approaches effectively overcomes the chaotic amplitude fluctuations previously associated with intracavity-doubled lasers.3

The benefits of these solid-state sources, when compared to water-cooled lasers, are numerous. They offer a much smaller footprint, more than an order-of-magnitude improvement in optical noise performance, and a hundred-times-improved wall-plug efficiency; also they require no external cooling water. Hence, these lasers have been embraced by the scientific research community, and diode-pumped green systems have essentially displaced argon-ion lasers as pump sources for modelocked Ti:sapphire lasers. As a result, all-solid-state Ti:sapphire-based systems are enabling the emergence of ultrafast laser applications such as terahertz imaging, two-photon microscopy, and ultrashort-pulse micromachining.

Even more impressive is how quickly the CW diode-pumped sources have been implemented in industrial and medical applications in which environment and usage can be a lot more demanding than in research. Though not addressed here, a major impact in the medical area has been the replacement of water-cooled ion lasers with diode-pumped sources for photocoagulation (see Laser Focus World, June 1996, p. 143).

Increasing data-storage capacity

Within the computer industry there has been a surge in the use of high-power diode-pumped green-output lasers as material-processing tools for disk drives and storage media. Most recently, disk texturing has become an important step in the production of hard-disk drives. In normal operation the data read/write heads of a hard disk fly above the disk surface on a cushion of air created by the rapid spinning of the disk. When powered down, the disk stops rotating and the head comes to rest on its surface. Because both disk and head are super-polished, they can form an optical contact and become bonded together. The result of this stiction is catastrophic failure of the drive.

In order to prevent stiction, the surface of the disk must be roughened or textured. Traditionally, this has been done mechanically with an abrasive material, such as a diamond slurry. The result is a relatively uncontrolled roughening of the disk with ridges of varying heights. While this solves the stiction problem, it restricts the performance of the disk by reducing the storage capacity—the capacity decreases as the head-to-disk separation is increased.

Laser disk texturing was introduced a few years ago to circumvent this problem by roughening the disk surface with pulses from a high-spatial-mode-quality, diode-pumped Q-switched laser that melts spots on the surface of the disk. The melted spots reharden into small crater-like "bumps" about 5 to 20 mm in diameter with heights of less than 25 nm. The storage capacity of the disk is not reduced because the bumps are more uniform, at a lower height, and the texturing process can be confined to a particular location of the disk—the landing zone—allowing the rest of the disk surface to be super-polished. The other advantages of laser texturing are faster throughput and reduced cost.

While diode-pumped infrared (IR)-output Q-switched lasers have proven to be a very reliable source for this application, advances in texturing processes are requiring reduced diameter and height tolerance of the bumps. These para meters are related to the wavelength and pulse-to-pulse stability of the laser source. By switching to a diode-pumped CW 532-nm source, hard-disk manufacturers have improved the amplitude stability of the beam and can focus it to smaller spot sizes.

In a related area, diode-pumped CW visible-output laser sources are being used to produce the next generation of floppy diskettes. Today’s 3.5-in. diskettes have a storage capacity of 1.44 Mbyte but the new Imation (Oakdale, MN) 3.5-in. Super Disk diskette provides more than 80 times the storage capacity. A major benefit of this technology is that the disk drive for the Super Disk is fully backward-compatible with existing 3.5-in. diskettes. The increased storage capacity of this new generation of diskettes is achieved by etching a servo pattern into them. The drive then uses a diode laser to read the servo pattern and align the read/write head.

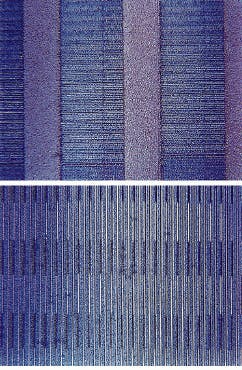

The precise positioning combined with a high-density metal particle pigment and dual-layer coating technology allows the Super Disk diskettes to use 2490 data tracks/in. compared with just 135 tracks/in. for conventional diskettes (see Fig. 1). The etching pattern was initially produced with a high-power green laser beam from a water-cooled argon-ion laser, but manufacturers have now changed to the 2-W Millennia II 532-nm source because of improved beam pointing, better long-term stability, and the other benefits mentioned previously. In addition, the reduced utility and maintenance costs of a solid-state source are significant in a manufacturing environment.Subtitling films

Similar economic reasons are given for the integration of diode-pumped CW green-output lasers into another material-processing application—film subtitling. A large percentage of the world`s population can enjoy movies only with the help of subtitles (see Fig. 2).The subtitling is done in several steps. First the film is transferred to a time-coded videotape and the dialogue broken down to fix the start and end point of each subtitle. The translation is then prepared in the desired language. The accuracy of both the translation and subtitle synchronization with the dialogue is checked using real-time video subtitling. Once this is achieved, the data—including titles, timecodes, text, and subtitle height—are stored on disk for the film-engraving process.

A laser beam engraves the subtitles by burning off the emulsion layer of the film to reveal the translucent background, which subsequently appears white under projection. The letters and blanks in the subtitles are created with computer-controlled x-y scanners and acousto-optic modulators in the laser-beam path. This market has traditionally been served by high-power argon-ion lasers but subtitling manufacturers have now successfully integrated 5-W CW green-emitting diode-pumped lasers into their machines. With no high-power electrical requirements and no need for a high-capacity water chiller or for special infrastructure, the technology offers lower initial investment costs and lower operating costs.

In other areas the advent of compact high-power, diode-pumped visible lasers is spurring development of analytical and inspection techniques as on-line diagnostics for industrial process control. In the semiconductor industry, for example, high-power diode-pumped CW green lasers are being used for wafer inspection. In the area of analytical tools, ChemIcon Inc. (Pittsburgh, PA) has developed the Falcon Raman chemical imaging microscope for industrial and biomedical applications including nondestructive failure analysis and process monitoring.

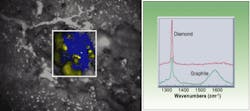

In this instrument a Raman spectrum is obtained by analyzing the scattered light from a laser-irradiated sample; it provides molecular vibrational information that, for example, can be used to help identify the chemical composition of the sample. The ChemIcon system uses a fiber-coupled 2-W Millennia II 532-nm laser as an excitation source. A liquid-crystal tunable filter (LCTF), Raman imaging spectrometer, and cooled charge-coupled-device (CCD) detector with optical microscope efficiently acquire confocal Raman spectra and Raman images. The instrument provides high-fidelity images of a sample with a spatial resolution of 250 nm, which simultaneously reveals molecular composition, molecular structure, and morphology.

Application areas include analysis of automotive surface coatings, polymer blends, emulsions, and actinide-contaminated soils and incinerator ash. In addition, volumetric imaging of surface structures in semiconductors is possible. Still other application areas are pathology and cancer detection, mineralogy, exobiology (the search for life on other planets; see Fig. 3), in situ monitoring of heat exchanger corrosion at high temperatures and pressures, and in situ stress analysis of microscale actuators in silicon micromechanical (MEMS) devices. The compact size and the wall-plug convenience of the diode-pumped laser source ensure that the Raman instrument can be installed in virtually any environment, and the high-power, low-noise output ensures that the images have good signal-to-noise ratios.In summary, the new generation of high-power visible-output diode-pumped lasers has truly been embraced by the customer base. Integration into industrial and OEM applications is proceeding rapidly. With today’s total diode-pumped laser sales at less than 10% of the worldwide nondiode-laser market, the potential for growth is extremely high—these compact all-solid-state sources will continue to chip away at the markets traditionally dominated by gas and lamp-pumped laser systems.

There are certainly technological challenges to be addressed along the way. Higher-power diode sources are needed, for example, that will enable higher-power diode-pumped systems to be more price competitive with existing technologies. And breakthroughs in nonlinear optical materials will enhance the utility of these lasers. Recent advances in these areas, such as the release of 40-W diode bars from Opto Power Corp. (Tucson, AZ) and the successes in "engineering" of quasi-phase-matched nonlinear materials through periodically poling techniques, demonstrate that these obstacles are surmountable.

One can anticipate that in the near future diode-pumped solid-state lasers will provide even higher powers, a wider selection of visible wavelengths, and access into the blue and UV spectral regions. This, coupled with the emerging industrial opportunities, indicates that the aggressive market growth projections are well founded.

ACKNOWLEDGMENTS

The author would like to thank John Seigel and Carol Ritacca of Imation for providing the images used in Fig. 1 and also Patrick Treado of ChemIcon Inc. and the University of Pittsburgh, Nicole Kline from the University of Pittsburgh, and Allan Treiman of the Lunar & Planetary Institute for making available the images used in Fig. 3.

REFERENCES

1. V. Magni et al., Opt. Lett., 18, 2111 (1993).

2. W. L. Nighan Jr. and J. Cole, Advanced Solid State Lasers Conference, paper PD4 (OSA, San Francisco, CA; 1996).

3. T. Baer, J. Opt. Soc. Am. B, 3, 1175 (1986).

BRUCE CRAIG is Industrial & Scientific Systems marketing manager at Spectra-Physics Lasers, 1330 Terra Bella, POB 7013, Mountain View, CA 94039-7013; e-mail: [email protected].