ULTRAFAST LASERS: Multiphoton drilling liberates oils, unharmed

Because amber may have inclusions (sometimes in the form of insects) that are incredibly well preserved, this material has been invaluable to paleontologists. Certain specimens of quartz can have organic inclusions too, in the form of petroleum-fluid-filled vacuoles that provide unique information to geologists on the composition of ancient hydrocarbon fluids.

Now, scientists at CSIRO Petroleum and MQPhotonics Research Centre (both in Sydney, Australia), Femtolasers Produktions (Wien, Austria), and the Laser Zentrum Hannover (Hannover, Germany) have come up with a way to use ultrafast-laser ablation to open individual inclusions without altering the oil inside, giving geologists a pristine view of the past.1

Preserving the variety of samples

“Quartz is the most common mineral that forms sand, and many petroleum reservoirs are porous sandstones. Fluids can be trapped in these grains in healed imperfections,” explains Herbert Volk, organic geochemistry team leader at CSIRO Petroleum. A single piece of quartz can contain different groups of fluid inclusions, each with a different molecular and/or isotopic makeup that relates to its own geological event.

Existing techniques for extracting the hydrocarbon samples include mechanical crushing or thermal decrepitation (cracking) of the quartz, followed by extraction of the fluid with heat or solvents and analysis by gas chromatograph-mass spectrometer (GC-MS). While these techniques can produce detailed molecular data, the samples are extracted in bulk, resulting in the loss of individuality in the data for the different groups of inclusions.

Previous attempts to extract the fluids using lasers (such as neodymium:YAG and erbium:YAG lasers) resulted in coupling to the fluid rather than the surrounding quartz and were hard to control.

The new technique replaces the YAG laser with a high-energy ultrafast oscillator system from Femtolasers (the Femtosource scientific XL 200), which emits 50 fs pulses centered at 800 nm and with a 50 nm spectral width. An associated GC-MS has a 20× microscope objective with a numerical aperture of 0.4, which focuses the beam onto the sample. The resulting peak intensity at focus is greater than 1014 W/cm2, causing multiphoton absorption in the quartz–and allowing clean nonthermal drilling of holes.

Oscillator was chosen

An ultrafast oscillator was chosen over an ultrafast amplifier, lowering costs; in addition, because the multiphoton-based drilling of quartz works best just above the ablation threshold, the higher output of an ultrafast amplifier would have to be greatly attenuated anyway. A Herriott-type multipass cell was integrated into the Femtolasers oscillator, which simultaneously reduced repetition rate and raised the per-pulse energy to the desired level.

“The evaporated hydrocarbons are swept into a first cryo-trap in a stream of helium that flows through the laser chamber at a rate of 100 mL/min,” explains Volk. The hydrocarbons are then released from the first trap, “refocused” in a second trap with a stepped-down helium flow, and then separated on a GC column before MS detection.

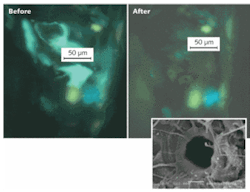

In the experiment, 160 nJ pulses at an 11 MHz repetition rate were focused onto a quartz crystal, targeting an inclusion on the order of 50 µm in diameter (see figure) and drilling a 2-µm-diameter hole through to it (a 10 µm inclusion was targeted first, but did not produce enough petroleum for a clear GC-MS signal). The GC-MS analysis revealed a number of low- to mid-molecular-weight hydrocarbon compounds with a distribution similar to what was found for bulk crushing. Not detected were alkenes and ketones that could have been formed from high ablation temperatures; this showed that the drilling was “cold” (multiphoton) and not “hot” (thermal).

“The advantage of our femtolaser approach is that single inclusions can be analyzed,” says Volk. “This was not possible in a controlled way with the traditional Nd:YAG laser system, and is also not possible with the bulk crushing method. The disadvantage is that the amounts that are liberated from a single inclusion are minimal and hence challenge the detection limit of conventional GC-MS instruments. We hope to improve the inlet system so that we minimize the loss of compounds between the laser chamber and the GC-MS instrument.”

Volk notes that the use of a time-of-flight secondary ion mass spectrometry for the detection of biomarkers, as proposed by Sandra Siljeström and her colleagues at SP Technical Research Institute of Sweden (Borås, Sweden), could enhance the sensitivity of the system.2 “We are engaging with her to exploit synergies,” he says.

REFERENCES

- H. Volk et al., Org. Geochem. (2009), doi:10.1016/j.orggeochem.2009.05.006 (in press).

- S. Siljeström et al., Organic Geochem. 40, p. 135 (2009)

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.