WIDE-ANGLE OPTICS: Panoramic imager captures an unoccluded 260°

Using only two optical components, researchers from Bielefeld University (Bielefeld, Germany), the Australian National University (Canberra, Australia), and the University of Queensland (St. Lucia, Australia), have created a panoramic imager that fits over a standard 6 mm C-mount lens for a 1/2 in. CCD camera to give the camera an unobstructed 260° field of view (in other words, it sees out to 130° away from the optical axis in all directions).1 If such a camera were held by a photographer and pointed at the horizon, it would not only capture everything in front of, above, below, and to either side of the photographer; it would image a good portion of the photographer as well.

While useful for such purposes as surveillance and wildlife studies, extreme wide-field imagers usually suffer from obstructions somewhere in the field–a result of the catadioptric (mirrors plus lenses) design itself or of the struts needed to support the optics. The researchers eliminated design-related field obstructions by combining two optical systems–one refractive, which captures the central field portion near the optical axis; and one catadioptric, which captures a larger, annular field portion. In addition, because one optical element is mounted directly to the other, no support struts are needed.

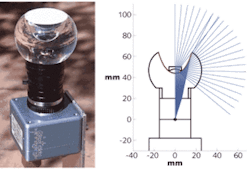

While one element is a simple plano-concave lens, the other is a custom-machined shape of Perspex (a transparent acrylic) with its outer surface almost spherical and its inner surface having the appearance of a hyperboloid, although its shape is actually mathematically much more involved. Part of the inner surface is silvered and reflects light from the annular-field portion down to the camera; the rest of the inner surface combines with the plano-concave lens to capture the central portion of the field (see Fig. 1).

To finish the Perspex shape after machining, the inner and outer surfaces were polished with fine dry and wet sandpaper, then with metal polish. After masking, the mirror surface was coated with silver by vacuum deposition; white paint was then sprayed over the silver to protect it.

Pixel-mapping

The two optical systems, which have fields that slightly overlap, project their images onto the same plane (see Fig. 2). The final image is created via pixel-mapping (using software). Because the reflective surface has a varying optimal depth of focus, the researchers chose to tolerate a slight blur in the outermost part of the field, which in addition ends up being mapped into only a small solid angle.Wolfgang Stürzl, one of the researchers, notes that chromatic dispersion is not a serious problem because of the large field of view (in other words, single camera pixels have quite large “acceptance angles” and as a result small angular deviations should not matter). “Also, in very low light conditions, geometric aberration will dominate,” he says. “However, for very small apertures in bright daylight, chromatic dispersion may be visible with high-resolution pixel sensors.”

In addition to the two-element panoramic imager, the researchers created another version with only one element (the Perspex shape) and a 200° field of view, and which relied on total internal reflection rather than a silvered surface. However, the single-element version had a larger field-related change in focus, as well as a drastic difference in magnification between the central and annular field portions.

The two-element Perspex panoramic imager has already been used for a reconstruction of the visual input of flying insects. Along with several potential applications in the areas of security and surveillance, Stürzl says the imager will be of use on visually controlled mobile robots. The researchers are now at work on smaller and lighter versions of the imager, and are exploring mass production.

REFERENCE

- W. Stürzl et al., Applied Optics 47(32) p. 6070 (2008).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.