Optical Data Storage: Ultrafast electron crystallography reveals performance limit of data storage media

Today's digital video discs (DVDs) and Blu-ray discs use nanosecond pulsed lasers to record information on a phase-change material (PCM) in different atomic states—various crystalline and amorphous structures. In an effort to obtain a more-thorough understanding of the time scales for the transformation of these states and, hence, to establish the speed limit of data recording, researchers at the California Institute of Technology (Caltech; Pasadena, CA) have adopted their ultrafast electron crystallography (UEC) technique to directly monitor the transient atomic configurations in PCMs.1

Beyond nanosecond timescales

Today's nanosecond lasers can transition a phase-change material from an ordered crystalline to an amorphous state (from a digital data "0" to "1") on nanosecond time scales. However, ultrafast lasers operating on femtosecond time scales make it possible to explore whether the PCM transitions are limited by laser speeds or by the fundamental physical properties of these materials.

In the UEC experiments conducted, a nanofilm of crystalline germanium telluride (GeTe)—a typical phase-change material—was illuminated with a femtosecond laser pulse followed by an ultrashort pulse of electrons. As the laser causes the ordered crystalline structure to transition to an amorphous state, the electron beam is scattered in a diffraction pattern that reveals an "image" of the atomic structure. By monitoring the diffraction patterns as a function of the delay time between the initial laser pulse and the probing electron pulse, it is possible to retrieve the evolution in time of the atomic-scale behavior of the materials, providing a four-dimensional (4D) visualization, in space and time, with both high spatial and temporal resolution.

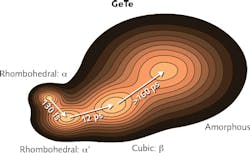

In the case of GeTe, the initial crystalline rhombohedral phase does not immediately transition to an amorphous stage; rather, transition of the rhombohedral to an interim cubic structure occurs in 12 ps (see figure). On a much longer time scale-hundreds of picoseconds-the nanofilm heating reaches equilibrium and the amorphous phase can be achieved, provided the system is excited with high-enough energy and is rapidly quenched.

The existence of this intermediate cubic stage was experimentally observed at Caltech for the first time, and could only be seen using the high atomic sensitivity of the UEC method. These results are also able to provide a more-general picture for PCMs. Because data recording depends on the presence of two clearly defined atomic states, the additional intermediate structure (which represents a precursor to the final amorphous phase) sets a limit on how quickly the crystalline-to-amorphous transition can occur and correspondingly limits the potential speed of data recording regardless of the speed of the writing laser used.

"Even adopting a laser faster than femtosecond, there will be a limit as to how fast this transformation can occur and data can be stored, just because of the physical nature of these phase-change materials," says Giovanni Vanacore, a postdoctoral scholar at Caltech and an author of the study. "It's something that cannot be addressed technologically—it's fundamental," concludes Jianbo Hu, a postdoctoral scholar at Caltech and first author of the paper.

REFERENCE

1. J. Hu et al., ACS Nano, 9, 7, 6728–6737 (Jun. 2015).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.