OPTICAL SWITCHES: 448 × 448 optical switch serves terabit systems at nanosecond speeds

Optical communication networks currently depend on electronic switching techniques to route traffic; however, next-generation supercomputers and terabit/second communications networks will require high-port-count all-optical crossconnect (OXC) switches with nanosecond switching speeds. Current optical switches can easily achieve such speeds, but port count is often limited. And vice versa, high-port-count switches typically suffer from slower switching speeds. But by expanding on previous research that used a wavelength-assisted routing scheme and a single arrayed-waveguide-grating router (AWGR) to create an OXC, researchers at the Institute for Infocomm Research and Nanyang Technological University, both in Singapore, have developed a 448 × 448 port-count OXC that switches at nanosecond speeds.1

A new OXC architecture

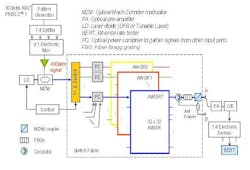

Previously, OXCs developed by other researchers used only a single AWGR. The AWGR consists of optical waveguides fabricated on a silicon substrate using lithographic processes, and its principal role is to route signals to different output ports based on the wavelength of the signal at its input port. However, the scalability of these single-AWGR OXCs was limited to port counts below 100 × 100 because the interchannel crosstalk noise increases as the number of AWGR ports becomes very high. To eliminate this problem, a new OXC architecture was designed based on a parallel array of AWGRs interconnected through a network of nanosecond-speed-capable optical switches and wavelength-division-multiplexer (WDM) fiber couplers.

In a proof-of-concept experiment, a 40 Gbit/s optical signal from a specially developed wavelength-tunable laser (with a 72 ns wavelength-tuning speed) is switched by a 448 × 448 OXC constructed using an array of eight parallel AWGRs. The signal is first sent into a 1 × 8 lithium niobate switch capable of switching at nanosecond speeds. The 1 × 8 switch then routes the signal to the correct AWGR based on its destination output port.

Next, the signal enters a 32 × 32 AWGR via an optical power combiner and, depending on its wavelength, is routed to a particular output port. At each output port of the AWGR, the dual-band WDM coupler further routes the signal to either one of its two output ports—again, dependent on the signal's wavelength. The unique cyclic routing property of the AWGR and the dual-band WDM coupler doubles the port count of the OXC, enabling high-port-count scalability.

Because commercially available WDM couplers have a wavelength range (stopband) that limits the number of channels that can pass through, serially concatenated fiber Bragg gratings (FBGs) are placed between the AWGR and the WDMs to recover the optical channels that would have been lost as a result of the stopband.

At the optical receiver, a 40 Gbit/s optical/electrical converter and a 1:4 electronic demultiplexer connected to a bit-error-rate tester (BERT) were used to analyze the performance of the switched signal.

Error-free performance

Based on analysis of switching performance for eight selected wavelengths each carrying 40 Gbit/s signals, BERT values less than 10-9 were obtained at power levels of -9 dBm when a fixed-wavelength distributed-feedback (DFB) laser was used as the optical source. The switching performance remained error-free even when the DFB laser was replaced with a wavelength-tunable laser (although the power penalty increased by 2 dB).

"As data centers become increasingly power-hungry, the energy inefficiencies of switches and interconnect systems are fast becoming areas of concern," says Yong-Kee Yeo, principal investigator of the switch project at the Institute for Infocomm Research. "If we do not improve the way we currently design switches and interconnect systems, we may soon find ourselves grappling with challenges brought about by high power consumption and severe thermal management problems." Although optical fibers are already used to interconnect racks in data centers, more could be done to reduce the optoelectronic conversions that are required in electronic switch fabrics. One possibility is to replace such electronic switch fabrics with a single-stage OXC.

REFERENCE

- Y.-K. Yeo et al., OFC/NFOEC 2010 conference paper OMP6, San Diego, CA (Mar. 22, 2010).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.