With a negative refractive index, a planar slab "superlens" can image features below the diffraction limit by recovering evanescent waves as well as ordinary free-space light waves. One approach to building such a device is to use a film of silver (Ag), which although it does not have a negative index, has a negative permittivity, which is sufficient to act on light with a transverse magnetic polarization. However, when fabricated as a thin enough film, Ag normally forms islands, resulting in a roughness high enough to interfere with the superlensing effect.

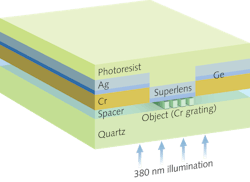

But by depositing a film of germanium (Ge) between a 15 nm layer of Ag and the chromium (Cr) sublayer, researchers at the University of Illinois (Urbana, IL), Hewlett-Packard Laboratories (Palo Alto, CA), and the University of California (Davis, CA) have made a superlens smooth enough (with a subnanometer roughness) capable of resolving at 1/12 the illumination wavelength. The object to be imaged was a grating in the Cr layer with a 30 nm half-pitch. At an incident wavelength of 380 nm, the grating was imaged at 1:1 into photoresist with high fidelity. A corrugated silver surface could be added to enable far-field imaging, say the researchers. Contact Nicholas Fang at [email protected].