ELECTRON MICROSCOPY: Lloyd’s-mirror technique extracts contour information from microscopic 2-D images

As nanotechnology continues to grow, researchers struggle to monitor the details unfolding at scales far below the threshold of human vision, such as thin-film growth and droplet coalescence. Scientists using an old-time technique have found a way to retrieve real-time three-dimensional information from two-dimensional surface-electron-microscope images.

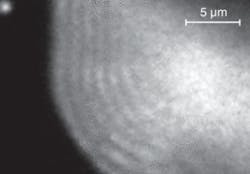

While investigating liquid gallium droplets spreading on the surface of a gallium arsenide substrate, David Jesson and colleagues at Monash University (Victoria, Australia) noticed that the edge of the droplets displayed so-called Lloyd’s fringes, an effect understood since 1834 (see figure). Lloyd’s fringes form when light reflected from a mirror (referred to as a Lloyd’s mirror) interferes with light coming from the source.

In the modern version of the effect, the scientists combine photoemission electron microscopy with the classic Lloyd’s-mirror optical geometry to determine the contour information of the coalescing gallium droplets. In this technique, UV light illuminates the droplets on the reflective substrate and forms Lloyd’s fringes near their edges, which are imaged using a photoemission-surface-electron microscope. The cathode immersion lens (part of the electron-microscope optics) may cause distortion of the fringes due to the influence of the surface topography on the uniform electric field, but the distortion is correctable with image processing. The fringe intensity varies with the height of the droplet, so the shape of the droplet surface can be reconstructed by simply counting the fringes, similar to counting the contour lines on a topographic map.

The resolution of the method is fine enough to allow detection of fringes spaced approximately 0.5 mm apart using a UV light source. Further development of Lloyd’s-mirror electron microscopy would enable resolution of features measuring hundreds of nanometers. Use of a synchrotron light source could achieve even higher resolution.

The team used the technique to investigate contact-line dynamics during reactive wetting of metal droplets, but the results of that study are secondary to the importance of the technique itself. The researchers believe the intensity and contrast of the fringes are strong enough to enable observations of real-time changes in surface topography.1 The technique could then be applied to create three-dimensional movies of nanoscale motion, such as magnetic changes in nanostructures being developed for use in computer memory, and growth of thin films and photonic crystals.

REFERENCES

1. D.E. Jesson et al., Physical Rev. Lett. 99, 016103 (July 6, 2007).

About the Author

Valerie Coffey-Rosich

Contributing Editor

Valerie Coffey-Rosich is a freelance science and technology writer and editor and a contributing editor for Laser Focus World; she previously served as an Associate Technical Editor (2000-2003) and a Senior Technical Editor (2007-2008) for Laser Focus World.

Valerie holds a BS in physics from the University of Nevada, Reno, and an MA in astronomy from Boston University. She specializes in editing and writing about optics, photonics, astronomy, and physics in academic, reference, and business-to-business publications. In addition to Laser Focus World, her work has appeared online and in print for clients such as the American Institute of Physics, American Heritage Dictionary, BioPhotonics, Encyclopedia Britannica, EuroPhotonics, the Optical Society of America, Photonics Focus, Photonics Spectra, Sky & Telescope, and many others. She is based in Palm Springs, California.