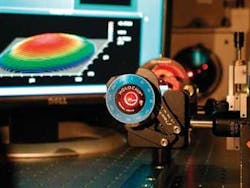

OPTICAL COMPONENTS: Commercial singlet has continuously variable focus

A fluid-based singlet lens with a continuously variable focal length, commercially introduced by Holochip (Albuquerque, NM), promises to expand the options available to lens designers and laboratory researchers alike. Unveiled at CLEO/QELS 2007 (May 6-11; Baltimore, MD), the lens has an elastic polymer membrane that encapsulates a nontoxic fluidic polymer; fluid brought into or out of the chamber created by the membrane alters the focal length. For example, the focal length of a lens with a 10 mm clear aperture can be changed from plus infinity to 18 mm.

While fluid-based lenses with a continuously variable focal length based on electrowetting have been commercially available for years (see www.laserfocusworld.com/articles/192730), they offer clear apertures of only a few millimeters at most. In contrast, the mechanically actuated Holochip lens-dubbed the “adaptive polymer lens” (APL)-allows clear apertures of up to 70 mm (larger sizes have modifications to compensate for effects of gravity).

The mechanism can be designed to be actuated by hand or by a servo motor. The exhibited lens has a typical root-mean-square wavelength error (at 633 nm) of 0.042 to 0.079 waves, depending on focus, and a transmission of greater than 90% across the visible spectrum without the benefit of antireflection coatings (with 96% or better expected in the future). Transmittance in the near-UV (390 to 450 nm) and near-IR (1 to 2.1 µm) is greater than 80%. “We will be able to significantly expand this range and hit transmission windows outside the range of 390 to 2100 nm by selecting appropriate materials for the lens membrane and core,” says Rob Batchko, cofounder and CEO of Holochip.

While the APLs exhibited at CLEO 2007 have focal lengths ranging nominally from 2 cm to infinity on the converging side, they can also operate in a diverging mode (negative focal length). “With our apologies to the movie industry, we felt justified to reinvent the phrase ‘to infinity and beyond,’ ” notes Batchko.

Patents contributed by Batchko and by subsequent research and development at Holochip form a substantial portion of the company’s intellectual property, he says. For some of the variants on the technology, Holochip exclusively licensed worldwide intellectual-property rights from the University of Central Florida (UCF; Orlando, FL) and Louisiana Tech University (Ruston, LA). Collaborations between Holochip and the research groups of Shin-Tson Wu (UCF) and Kody Varahramyan (Louisiana Tech) are ongoing and expanding, according to Batchko.

The APL was created to fulfill unmet needs of lens designers, he explains. For example, an optical engineer may have only a short window of time to demonstrate an idea, but no lens available with the right focal length. “For the researcher who needs a quick verification of a concept, this product can be a real time-saver,” he says. “Catalog companies will want to be a part of this opportunity to serve their existing client base, and several discussions we have already held testify that this is indeed true.” Batchko adds that Holochip expects to be announcing distribution partnerships and to have the APL available in optical catalogs before 2008.

Integrating with lens design

Commercial lens-design programs are an essential part of the optical R&D process, and typically include numerical models of stock catalog lens designs. Holochip is working with Zemax (Bellevue, WA) and Code V (Optical Research Associates; Pasadena, CA) program developers and lens designers toward modeling the APL for these programs, says Batchko. To build the model, metrology is first performed on the lens membrane at a number of settings throughout the range of focal lengths of the lens. Once the surface profiles and associated aberrations are known, implementation of the model will be completed in two phases: discrete and continuous.

In the discrete phase, a model with N discrete lens forms representing N focal lengths will be created (for use in Zemax); the choice of focal lengths and associated aberrations that give the best system performance could be included in an optimization routine. In the continuous phase, which is potentially a much more powerful and accurate option, a model with continuously variable parameters is created; Holochip is working with Optical Research Associates and Zemax to integrate the APL’s lens surface into optimization routines in this fashion.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.