QUANTUM-CASCADE LASERS: Quantum-cascade lasers enable gas-sensing technology

Since the first demonstration of a quantum-cascade (QC) laser in 1994 by Faist et al., there has been extensive research to increase performance levels to enable practical applications. For one of these applications-gas sensing-research has mainly focused on improving operating-temperature parameters, optical output power, and spectral behavior of QC lasers.

For QC lasers to reach volume production, the major technology development challenges involve reproducibility, time, quality, and cost. The sensor and QC-laser manufacturing communities are now putting the development emphasis on stringent specifications, burn-in processes, extracting mean-time-to-failure (MTTF) parameters, and drafting the unavoidable supply contract “warranty” and “product liability” clauses.

Thirteen years after its invention, the implementation timeline for QC lasers looks, not surprisingly, similar to many novel semiconductor devices developed in the past. For such technologies the elapsed time from research concept to market implementation was in the range of 10 to 15 years. Although QC lasers are poised to prove themselves in many applications, technology developments are ongoing toward the goal of reliable volume production-a necessity for the integration of QC lasers into commercial gas-sensing instrumentation.

Current state of the art

Perhaps the best way to assess the current state of the art for volume-production QC lasers is to start from the top of the food chain and understand the market requirement from the end-user point of view. As an example, the continuous-emission-monitoring (CEM) market-which includes engine emission and power-plant stack monitoring-is very competitive, with a range of different gas-sensing technologies, such as chemiluminescence, nondispersive infrared, and Fourier-transform spectrometry (all at various degrees of technology maturity), each trying to increase its market share. Among these technologies, QC-laser-based gas sensors are like newborns: although they theoretically offer orders-of-magnitude improvement in performance, a fair amount of demonstration and convincing is necessary in this conservative market.

Customers are often reluctant to buy an unproven new sensor when there are other mature systems on the market. With this in mind, demonstration of the unique advantages of the QC laser is often necessary, with specifications, burn-in performance, MTTF parameters, traceability, and warranty period having a significant impact.

For the competitive CEM market, another important factor is cost. Here, it can be difficult to justify a system price above the market, despite better performance, because of the risk of an unproven, new technology. A QC-laser-based system, therefore, may be priced below market, which can have repercussions that can be felt down to the component supplier.

Volume production

After several years of research, groups developing QC lasers are preparing for volume production and upgrading their infrastructure to meet the stringent requirements for these III-V semiconductor devices. Among the various groups manufacturing QC lasers, Xavier Marcadet from Alcatel-Thales 3-5 Lab (Palaiseau, France) and Antoine Muller from Alpes Lasers (Neuchatel, Switzerland) are moving beyond burn-in times of 2000 hours minimum and moving toward volume production.

Named after its members Alcatel-Lucent and Thales, the 3-5 Lab and its synergy of III-V material research has recently acquired a Riber 49 multiwafer molecular-beam-epitaxy (MBE) production machine. The equipment is dedicated to the development and production of quantum-well infrared photodetectors (QWIPs) and QC lasers. “It allows us to master the whole production line for the manufacture of large focal-plane-array infrared detectors and IR semiconductor-laser sources,” says Marcadet. In fact, the new MBE machine, together with other III-V sophisticated device processing equipment, gives the group the capability of high-throughput production at considerably reduced technical risk and lower development cost.

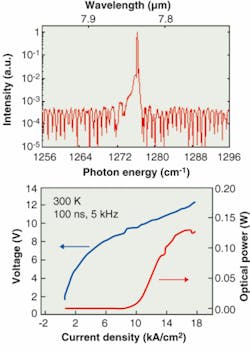

“For QC lasers, semiconductor layer thickness and composition tolerances are very tight,” Marcadet adds. “The new MBE setup allows us to control them below 1% and achieves excellent uniformity requirements on the platen with outstanding run-to-run reproducibility. In addition, the defect density is very low and thus compatible with a very high yield in the fabrication of distributed-feedback (DFB) QC lasers. The recent work and know-how developed at 3-5 Lab enables-using MBE growth and top-grating design modeling tools-the volume manufacture of room-temperature DFB QC lasers with side-mode suppression ratio of more than 30 dB for an operating temperature specified by the customer.” The QC lasers also offer good light-current-voltage (L-I-V) curves (see Fig. 1).In its effort to bring QC lasers to market, Alpes Lasers introduced strict quality control at the very beginning of its small-series production. “Similar to the vast majority of cutting-edge high-tech companies, Alpes Lasers is experiencing a highly dynamic development in the battle of bringing the QC laser from laboratory tables to a mature and widely accepted industrial product,” Antoine Muller says. “The system of traceability being used is proving to be flexible enough to be scaled and adapted for larger series production.”

Alpes’ quality process was impacted by the selection of its QC lasers to be aboard NASA’s mission to Mars scheduled for 2009. “Our laser devices have been selected as a key component of the space-born spectroscopic instrument,” says Muller. “The results of several subsequent audits from NASA quality-assurance specialists performed directly in the facilities enabled Alpes Lasers to be enrolled into NASA’s List of Approved Suppliers.”

Gas-sensing applications

In addition to QC-laser manufacturers taking important steps to adapt to a rapidly developing market, some system manufacturers incorporating these devices are taking matters into their own hands by making sure that QC lasers are a good fit for the intended applications.

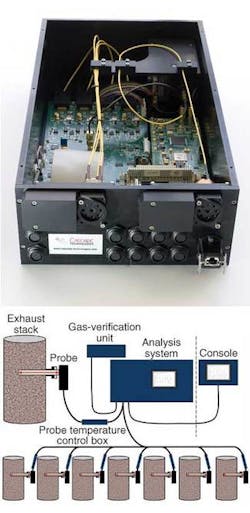

By working closely with a few partners, Cascade Technologies is creating precise device specifications that have been developed in concert with the QC-laser manufacturers. Also, each DFB device follows a specific set of factory-acceptance tests to confirm it meets specified mounting tolerances and performance criteria such as side-mode suppression ratio, optical output power, emission wavelength at stated operating temperature, output beam quality, vibration and acceleration requirements, and burn-in test requirements. By using existing industry infrastructure, the QC lasers used in Cascade systems are now in fiber-pigtailed butterfly package format, complying with most of the assembly tools and reliability test benches available in the telecom industry.

The fruition of these efforts has been the development of a commercial gas-sensor platform that can be applied to a variety of applications including emissions monitoring and process control (see photo, p. 90). The sensor utilizes the high spectral quality and selectivity associated with the QC laser to record the IR absorption spectra of gases ofinterest. Such properties are fully exploited, allowing the QC-laser sensor to overcome many of the concerns-such as cross interference, measurement drift, sensitivity, and response time-typically associated with traditional technologies. The capability to switch up to four lasers, ranging in wavelength from 3.5 up to 20 μm, to eight separate measurement points also provides real opportunities to compete on price.

In emissions-monitoring applications, fiber-coupled in situ gas-sample probes negate any concern over gas-sample handling, ensuring that measurement integrity is never compromised. Typical gas-measurement capability includes gases such as nitrous oxides, sulfur oxides, carbon dioxide, carbon monoxide, ammonia, and hydrocarbons. Further design features such as extended temperature operation (-20°C to +55°C), small footprint, and limited component count make the sensor well-suited to a variety of industrial applications.

Like many groups developing QC lasers, the sourced Cascade devices will undergo more than 2000 hours of reliability study, allowing MTTF parameters to be specified in the near future. The usual warranty provided for our gas-sensing systems currently varies from 12 to 36 months, depending on the application.

Positive outcomes are emerging from implementing volume production and proper validation processes on QC lasers. Along with a noticeable improvement in gas-sensing performance parameters, volume cost reduction is allowing system price decreases to meet market demands. By consistently tackling the challenges of QC-laser volume manufacturing, carrying out tight testing procedures, implementing quality-control systems, and reaching adequate device costing, QC-laser developers and manufacturers can compete in the marketplace. By continuing to build consumer confidence in QC-laser products, it should be easier for customers to digest the dreaded warranty and product-liability clauses found in supply contracts.

About the Author

Erwan Normand

Technical Director, Cascade Technologies

Erwan Normand is technical director at Cascade Technologies (Glasgow, Scotland).

Iain Howieson

Director of R&D, Cascade Technologies

Iain Howieson is director of R&D at Cascade Technologies (Glasgow, Scotland).