QUANTUM CRYPTOGRAPHY: Telecom-band single-photon source is electrically driven

The first electrically driven single-photon source at a telecommunication wavelength (approximately 1300 nm) has been developed by researchers at Toshiba Research Europe and the University of Cambridge (both in Cambridge, England).1

The researchers developed the single-photon source as a generator for a quantum-key-distribution (QKD) system. “A QKD system is unique in being able to guarantee that digital keys are exchanged with no possibility that a third party has accessed them while in transit,” says researcher Martin Ward. “Systems on the market today use an attenuated laser to generate the photons on which the key is encoded. However, an attenuated laser will always produce more than one photon in some pulses and this presents an opportunity for an eavesdropper to tap off photons to measure. Although we have previously shown that we can mitigate the risks by sending decoy laser pulses, the highest bit rates are achieved with a single-photon source. In most commercial systems, keys would be distributed over optical fiber. Our light-emitting-diode (LED) device is the first electrically driven single-photon source at a fiber wavelength.”

Optimized growth process

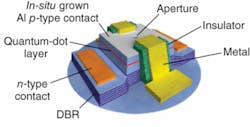

To achieve single-photon operation, the research team uses quantum dots in a planar microcavity to generate single photons within an LED structure (see figure). Although single-photon LEDs have been fabricated that operate at approximately 900 nm, previous work at telecom wavelengths has suffered from high dot densities that arise from fabricating the larger dots needed for these energies. Single-photon emission at approximately 1300 nm from quantum dots in small optical structures has previously been observed, but some residual multiphoton emission remained and optical excitation was required. The researchers optimized the quantum-dot growth process within a planar LED cavity for electrical excitation.

The planar device was grown using molecular-beam epitaxy and consists of a gallium arsenide (GaAs) cavity containing a carefully grown indium arsenide (InAs) quantum-dot layer. The GaAs/InAs structure is topped with a thin beryllium-doped layer topped by a 75-nm-thick aluminum (Al) layer that forms a nonannealed p-type ohmic contact. Apertures with diameters on the order of 1 µm were etched into the Al layer to collect emission from the quantum-dot layer. Electrical connections were run to the Al layer on top of an etched mesa and diffused n-type ohmic contacts were made to the top two silicon-doped layers on the distributed-Bragg-reflector (DBR) base of the LED.

Electroluminescence-emission spectra were recorded for constant bias and for pulsed operation. For constant bias, a clean emission line at approximately 1283.5 nm increased in intensity linearly with applied current-likely due to emission from a neutral or charged single exciton. Less-intense emission lines at around 1285 nm are probably due to more-complex (charged) excitonic states. For pulsed excitation, a 0.14 nm Stark shift of the line to longer wavelengths was observed, along with spectral broadening due to time-varying Stark shifts.

As the spectrally filtered emission passed to an InGaAs avalanche photodiode, the researchers measured the decay time of the electroluminescence to be approximately 1.3 ns (although taking into account detection jitter and the finite excitation pulse length of nominally 220 ps, they estimated the real lifetime of the dot’s emission line to be closer to 1 ns). In addition, a slower component (close to 10 ns) is also visible, but is tentatively attributed to a dark exciton that is repopulating the allowed exciton.

By taking advantage of the time-varying Stark shift of the emission from the LED and controlling the pulse rate, multiphoton emission can be eliminated and the 1 ns single-photon emission pulses can be isolated. Correlation measurements on the LED were used to demonstrate that multiphoton emission had been suppressed five times below that of a laser of the same average intensity.

“We performed this work as part of the Q-LED project with support from the U.K. Department of Trade and Industry,” Ward notes. “We are working with other organizations in the EU on the SECOQC (Development of a Global Network for Secure Communication based on Quantum Cryptography) project, which we hope will be contributing to the security of crucial networks within a few years.”

REFERENCE

1. M.B. Ward et al., Appl. Phys. Lett. 90, 063512 (2007).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.