OPTOFLUIDICS: Miniature stretchable dye laser tunes in the visible

Small, broadly tunable lasers can be of great use in spectroscopy (see www.laserfocusworld.com/articles/259939). In the interest of developing such lasers for use in the visible spectrum, researchers at the California Institute of Technology (Pasadena, CA) have created a stretchable optofluidic dye “laser on a chip.”1 Because the chip is made of polydimethysiloxane (PDMS) polymer, a tug by a mechanical actuator quickly and precisely changes the period of the device’s distributed-feedback (DFB) geometry, and thus the output wavelength. While a single laser of this type might have a tuning range of 30 nm, arrays of lasers on one chip (or, alternatively, changing the dye in a single laser) potentially allow for tuning across the entire visible spectrum.

Replicated laser

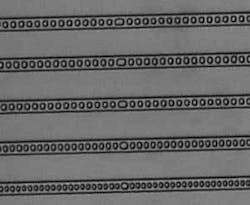

Using soft-lithographic replica molding, the researchers fabricated an optofluidic DFB waveguide-laser cavity; the 2 × 3 µm cross section of the waveguide ensured single-mode operation (see figure). Periodic PDMS posts spaced 3080 nm apart along the 1 cm waveguide defined a 15th-order DFB Bragg grating and also kept the waveguide from collapsing. A solution of Rhodamine laser dye with a refractive index of 1.409 was introduced into the waveguide, the cladding of which had a refractive index of 1.406.

The 3080 nm DFB period results in a 15th-order resonant wavelength of 577.8 nm and a free spectral range (FSR) of 41.3 nm (other DFB orders are possible depending on the dye used). At most, two resonances are supported within the FSR, but gain discrimination ensures that only a single longitudinal mode actually lases. The laser is optically pumped by an Nd:YAG laser emitting 6 nm Q-switched pulses at a 532 nm wavelength.

The waveguide serves as a microfluidic channel; if need be, the dye within the waveguide can quickly be replaced by other dye types. The dye can either be flowing, to replace dye bleached by the pump-laser light, or remain unmoving in the waveguide (acceptable for some experiments with low levels of pulsed pump light). The researchers tuned the laser by gluing its two ends to micrometer stages (one with a resolution of 1 µm) so that the laser was suspended between them, and moving one stage. A tuning range of 565 to 594 nm (15th order) was achieved with Rh6G dye; another dye, Rh101, resulted in a 613 to 638 nm range (14th order).

The PDMS prototype endured stretching and relaxation without failure. “We tried 100 cycles without fatigue,” says Zhenyu Li, one of the researchers. “The excellent elastic properties of PDMS have enabled the material to be used for on-chip mechanical valves for microfluidic manipulations; such valves show no fatigue after 4 million actuations in which the deformation is larger than what we used (about 5%). The allowed elongation of PDMS given in its specification is 120%.”2

The proof-of-concept device is low in optical output. “We haven’t measured the average power yet because of the short pulse duration, low repetition rate (10 Hz), and small emitting area,” notes Li. “The emitted energy per pulse is expected to be less than 100 nJ, but the intensity can be as high as 50 kW/cm2 and can be seen by the naked eye. The device has not yet been optimized for maximum power because the pump shape is not matched to the laser-cavity shape. If high power is desired, the transverse laser dimension can be increased.”

In addition to its obvious application in visible/near-IR absorption spectroscopy, the stretchable laser would be well-suited for use in multiplexed biological and chemical sensors such as multiplexed surface-plasmon-resonance-based sensors and multicolor-fluorescence-actuated cell sorters, says Li.

REFERENCE

1. Z. Li et al., Optics Express 14(22) (Oct. 30, 2006).

2. M.A. Unger et al., Science 288 (April 2000).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.