A collaboration led by researchers at PRESTO (part of the Japan Science and Technology Corporation) and Osaka University (both of Osaka, Japan) has demonstrated how factors considered unimportant at larger scales are crucial for precise two-photon optical fabrication of subwavelength structures. For instance, the sensitivity of beam shape to polarization and numerical aperture (NA), previously ignored, can cause major fabrication errors when working with features in the 100- to 500-nm range. In addition, tradeoffs between exposure power and time, previously thought to be simple, turn out to have a nonlinear relationship. This phenomenon can be exploited to allow recording by nonzero diffraction orders. Finally, by doping a polymer with gold ions and exposing it with interfering beams of light, researchers have shown that surface-relief gratings consisting of metal nanoparticles can be produced in a single step.

Well known for inventing the ascending-scan two-photon technique and fabricating a 10-µm model of a bull (see Laser Focus World, October 2001, p. 17), the team, led by Hong-Bo Sun, is working on improving both precision and versatility. In particular, researchers had found that their technique of scanning a focal spot was flawed because the nominally circular beam was elliptical in its effect. Experiments showed that, where linearly polarized light was used, the spot could be up to 10% longer in the polarization direction than orthogonal to it.1

This effect is not apparent in other systems because it arises from the very high NA used to create the three-dimensional (3-D) focus needed to make the scan technique work. What usually approximates to a circular cylinder loses its circular symmetry as the NA approaches 1. At 0.7 NA, a polarized beam has strongly asymmetric electric-field components. Though this effect is large, says Sun and his team, it is easily eliminated by using either circularly polarized or nonpolarized light.

Relating elements to each other

Another important development has been a more sophisticated understanding of how various elements related to exposure—NA, power, and time—relate to each other. For instance, in some cases, the smaller the NA is made in the two-photon-polymerization optics (decreasing from 1.4 to 0.88), the shorter the z-axis of the 3-D focus becomes (z is the direction of the optical axis). This phenomenon, which occurs only for some irradiation powers and times, is ascribed by the researchers to the thresholding effect of the two-photon material. Only sufficiently high exposure—delivered in the right way—causes polymerization.

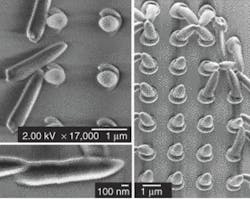

They pushed this idea further by showing that they could use the first order as well as the zeroth order of a diffracted beam to define features by two-photon polymerization. Normally this would be considered impossible with a two-photon process: the intensity of the first diffracted order is up to a hundred times lower than that of the zeroth-order light. However, if the power of the beam is chosen correctly, then the first order can be used by simply maintaining the beam's position over time. This is because the material's sensitivity is nonlinear, and the rate of polymerization increases rapidly with time. As long as the polymerization time of the first order can be balanced against the material breakdown time of the zeroth order, then both can contribute to the final structure (see Fig. 1). The research has resulted in different shape-scaling laws for varying power and exposure.2

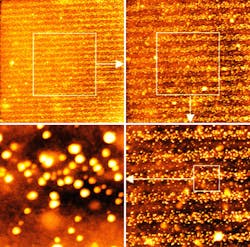

Another area that the team is investigating involves the irradiation of metal-ion-doped polymer films with beams that pattern at nanometer scale.3 Two interfering beams create a grating pattern made up of photoreduced gold nanoparticles. The particles are disc-shaped and an average of 65 nm in diameter and 11 nm high (see Fig. 2). After increasing past a critical exposure, the researchers noticed a new effect: the nanoparticles absorbed the incoming photons, redistributed the energy to their surroundings, and, as a result, caused a novel ablation effect (producing a surface-relief pattern on the polymer). An understanding of such issues will be important in the development of conductive and mechanically strong nanodevices that may use these materials.

REFERENCES

- Hong-Bo Sun et al., Appl. Phys. Lett.83(5) (Aug. 4, 2003).

- Hong-Bo Sun et al., Appl. Phys. Lett. 83(6) (Aug. 11, 2003).

- Koshiro Kaneko et al., Appl. Phys. Lett. 83(7) (Aug. 18, 2003).

Sunny Bains | Contributing Editor

Sunny Bains is a contributing editor for Laser Focus World and a technical journalist based in London, England.