Nanostructured metallic surfaces can manipulate light in surprising ways; for example, by patterning a metal surface surrounding an aperture, the directional emission of light passing through the aperture can be altered. Researchers at the Universidad de Zaragoza (Zaragoza, Spain), the Universidad Autónoma de Madrid (Madrid, Spain), and the Université Louis Pasteur (Strasbourg, France) have now put one form of this phenomenon on a solid theoretical footing.

By itself, a subwavelength slit in a metallic surface diffracts light substantially in all (one-dimensional) directions. But, when corrugations of the proper periodicity are fabricated into the metal on either side of the slit, the angular emission of the emerging light is narrowed.

"The system of single slit plus corrugations acts, for emission purposes, as a diffraction grating," says Luis Martín-Moreno, a professor at the Universidad de Zaragoza. "But this grating is a peculiar one, as the intensity of the emitters must be solved self-consistently. This means that one has to take into account not only how the light that exits the slit reaches the grooves, but also how the light that reaches the grooves is emitted and collected by other grooves and the slit. In general, the light re-emitted by the grooves is small and the grooves make a small contribution to the angular emission profile. But, under certain conditions, all that light wandering between indentations (corrugations or slits) interferes constructively on the indentations, and the final result can be understood as giving rise to the formation of a surface electromagnetic mode."

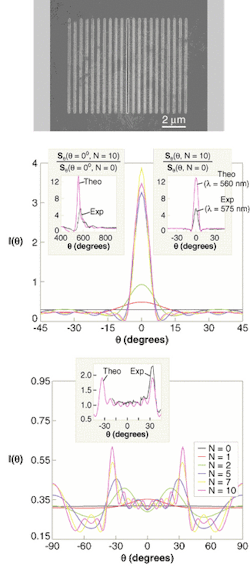

This "leaky" mode is a surface resonance that is coupled to radiation modes, so light eventually exits the surface and is radiated, explains Martín-Moreno. "Under these resonant conditions, the corrugations act as strong secondary emitters, and light is beamed in certain wavelength-dependent directions, with a very small angular width on the order of a few degrees," he says. To obtain experimental data for comparison with theory, the researchers fabricated a sample structure consisting of a single 40-nm-wide slit sandwiched between two arrays of ten 40-nm-wide grooves, each with a 500-nm period and a 100-nm depth (see figure).

When sandwiched between two corrugated arrays, a single fabricated subwavelength slit emits in a far narrower angular range than does a single slit with no features close to it (top). The calculated angular distribution of light transmitted through the slit narrows as the number of corrugations is increased (center, for light at 560 nm). Calculated and experimental angular distributions agree well to within a scale factor (center insets). The same calculations and experimentation are done for light at 800 nm (bottom and bottom inset).

The researchers optimized the structure for a finite periodic array, as their idea was to understand the mechanisms involved, says Martín-Moreno. "But there are no reasons why a strictly periodic system should be optimal and, actually, we are currently working on relaxing the constraint of periodicity. We already have preliminary results showing that the structure can be further optimized."

The structure could have applications in optical devices that require both a diffraction grating and a filter—that is, the diffraction-grating properties occur only for a narrow frequency range. The device could also be used as a very small multiplexer with a volume on the order of 1 µm3, according to Martín-Moreno. "In this 'effective diffraction grating,' the angular distribution of the emitted light is independent of the angle of incidence," he says. "Perhaps, the ability to create these modes running along a surface and, eventually, radiating to open space could be used to manipulate and carry light in very small structures."

REFERENCE

- L. Martín-Moreno et al., Phys. Rev. Lett. (April 25, 2003).