Some large-bore internal-combustion engines—in particular, slow-speed, two-stroke-cycle engines that run on natural gas—can have poor in-cylinder mixing caused by ineffective fuel delivery. Poor mixing causes thermal stratification, which generates elevated oxides of nitrogen emissions; it can also lead to partial combustion, which produces high carbon monoxide and unburned hydrocarbon emissions. The result is low engine efficiency.

Visualizing the fuel as it mixes in the combustion chamber aids in developing improved fuel-injection technology. In planar laser-induced fluorescence (PLIF), a seeded gas (with acetone as a tracer) fluoresces when irradiated with laser light, making the gas mixture visible for high-speed photography within an experimental combustion chamber.

A group led by Daniel Olsen at the Colorado State University Engines and Energy Conversion Laboratory (EECL; Fort Collins, CO) has used PLIF to conduct research into fuel mixing. The focus of much of the EECL research is on large-bore (>35 cm) natural-gas engines used for natural-gas compression.

High- and low-pressure (39 and 3.5-MPa) fuel-injection-valve designs were used to investigate the effects of injection pressure and fuel-valve design on charge mixing. The low-pressure valve is representative of stock fuel valves on the EECL's two-stroke-cycle, four-cylinder large-bore natural-gas test engine. The high-pressure valve is a developmental technology. In this initial study, the first phase of fuel injection and mixing are examined by injecting into ambient air.

A Cooke (Auburn Hills, MI) intensified charge-coupled-device (ICCD) camera was used in combination with a Spectra-Physics (Mountain View, CA) Nd:YAG laser for the PLIF data collection. The camera has a 12-bit dynamic range, 1280 × 1024-pixel resolution, and variable gate widths down to 3 ns, and was chosen for its single-photon sensitivity and ability to be accurately synchronized with other equipment. The laser operates at 266 nm and produces greater than 70-mJ/pulse at a 10-Hz repetition rate with a 5-ns pulse width. A pulse generator orchestrates the precise timing of the laser and camera.

Nitrogen, rather than natural gas, is used for safety purposes, as nitrogen is noncombustible. While the actual properties of acetone-seeded nitrogen are significantly different from those of natural gas, research on fuel injection into open air with various gas mixtures indicates that little variation (due to gas properties) is exhibited via the injection on plume penetration speed, jet shape, and dispersion.

High vs. low pressure

null

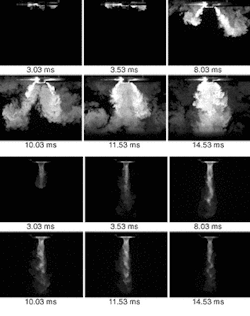

Images obtained with the ICCD show that the low-pressure fuel-valve jet has a number of distinguishing features (see figure). As the gas initially passes through the valve at low valve lift, it attaches to the wall of the cylinder head. As the valve reaches full lift (about 6-mm), the jet assumes a conical shape, creating vortices at the jet plume. Later in the process, the jet collapses and impinges on the piston, which is just below the 20 × 20-cm field of view. The valve begins to close at 13 ms and is fully closed at 23 ms.

The high-pressure jet produces a very different outcome, penetrating through the field of view in about one-third the time of the low-pressure jet. In addition, a clear, repeated diamond-shape pattern appears in the high-pressure jet once it is developed. This pattern arises from repeated compression and expansion waves and is characteristic of supersonic gas flow. The jet impinges on the piston below the field of view at much higher velocity than with the low-pressure jet. In the case of the high-pressure jet, mixing occurs after piston impingement, as opposed to the case of the low-pressure jet, in which a significant amount of mixing occurs during plume penetration.

Reduction of nitrogen oxide (NOx) emissions is just one area in which improved fuel injection has a dramatic effect: the enhanced mixing realized from high-pressure fuel injection produces far lower NOx levels for a given fuel consumption. Previous on-engine testing of the fuel valves examined in the EECL experiment has demonstrated that improving the fuel-injection process can significantly decrease fuel consumption and pollutant emissions. As a result of its testing, the EECL has been awarded follow-on projects for improving fuel-valve design and fuel-injection methodology. New fuel-valve designs and processes developed by the EECL will likely be implemented in field engines in the future.

Evelyn Roberts Levine

Evelyn Roberts Levine is a freelance technical writer based in West Bloomfield, MI; e-mail: [email protected].