Reading LIPS: the science of microstructuring using femtosecond lasers evolves

Researchers at Huai Hai Institute of Technology (Lianyungang City, China) have probed the effect of femtosecond laser fluence and pulse number on the formation of microstructures in crystalline silicon. To investigate the formation of holes, cracks, columns, and laser-induced periodic structures (LIPS), the team directed pulses from a Ti:sapphire laser emitting at 800 nm and a repetition rate of 1 kHz onto the surface of a 460-µm-thickness silicon wafer mounted on an x-y translation stage. They varied the number of pulses from N = 1 to N = 1000 and the fluence from 0.5 to 4 J/cm2.

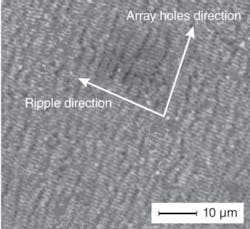

At fluences above 2.5 J/cm2, they determined that ripples of LIPS occur only for N less than 200, while columns form at fluences above 1 J/cm2 for N greater than 600. The researchers also reported that arrays of microholes (which lie parallel to the direction of incident polarization) gradually disappear and are replaced by the formation of LIPS (which lie perpendicular to the direction of incident polarization). Such characterization is useful for improving the durability of MEMS devices and other semiconductor structures, and to help scientists understand the effects of laser micromilling on materials and components. Contact Li Ji-Ming at [email protected].